Adhesion problems are an insidious concern to manufacturers in any industry with printing, painting, bonding, laminating, or coating applications. These problems settle into a production process, and they manifest in many different ways. An adhesion issue could look like a joint failure, uneven coating, cracking, pitting, peeling, and dozens of other catastrophic possibilities. Many of those issues sound purely cosmetic, but all adhesion failures have high costs to all manufacturers. Recalls and reputation damage are demonstrably hurtful to companies' profits. In industries working with high-reliability applications (automotive, medical devices), the results of adhesion failure have dangerous consequences.

Manufacturers throw everything they can think of at the issue but often can’t seem to get it under control consistently, so they end up getting cozy with the problem. If countenancing a certain amount of failure is the price of doing business, then what choice do manufacturers have?

They actually do have a choice, and they don't have to budget in failure. There are things any manufacturer can do to create a more adhesion-friendly environment and eliminate scrap and rework due to adhesion failure.

Here’s a list of highly valuable tips that, if fully implemented into a production process, will completely revolutionize any manufacturer’s approach to fixing adhesion problems and put a stop to profit loss due to these issues.

Tip #1: Define What Successful Adhesion Looks Like

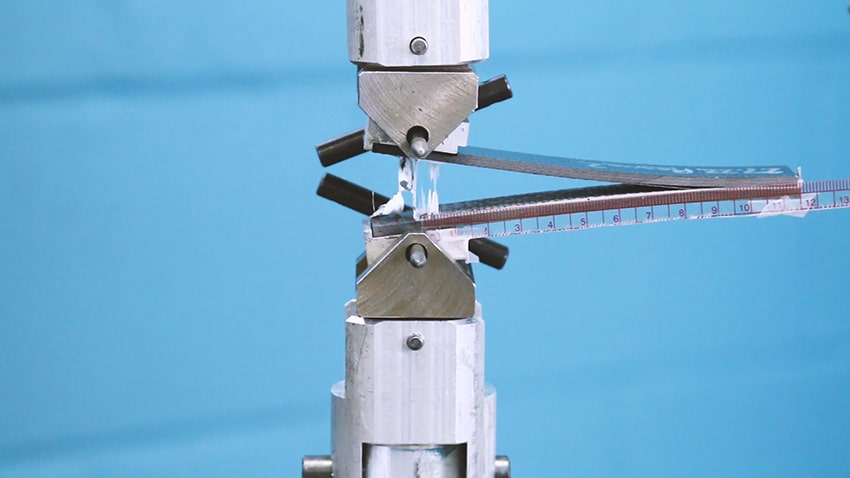

Manufacturers need to establish clear performance criteria for every step throughout an adhesion process and, ultimately, a welled defined goal for what successful adhesion looks like. When this goal has a number associated with it, there is more probability of repeating the desirable result. These standards might mean a printed label not fading after 1000 dishwasher cycles, stress test limits, or coatings withstanding hazardous environments. A similar metric needs to be applied to all of the steps prior to the finished product going out the door. Having clear goals throughout a production process allows manufacturers to make informed decisions about what changes need to be made.

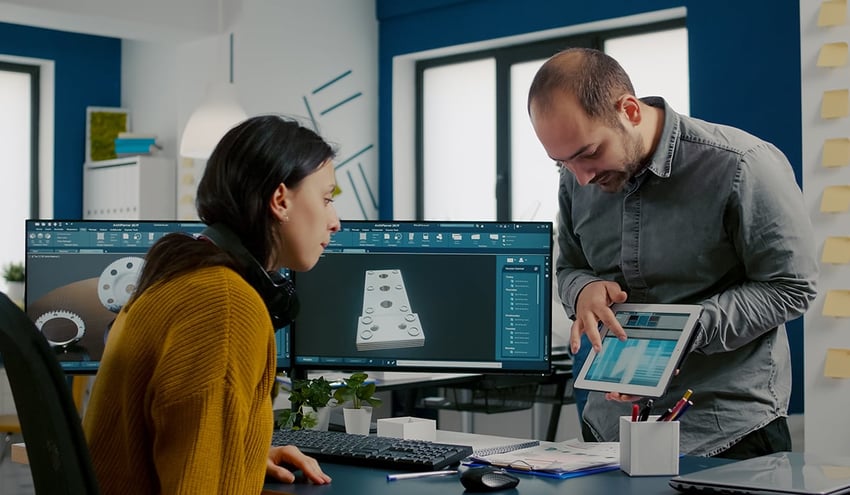

Rethink your adhesion manufacturing processes with Surface Intelligence.

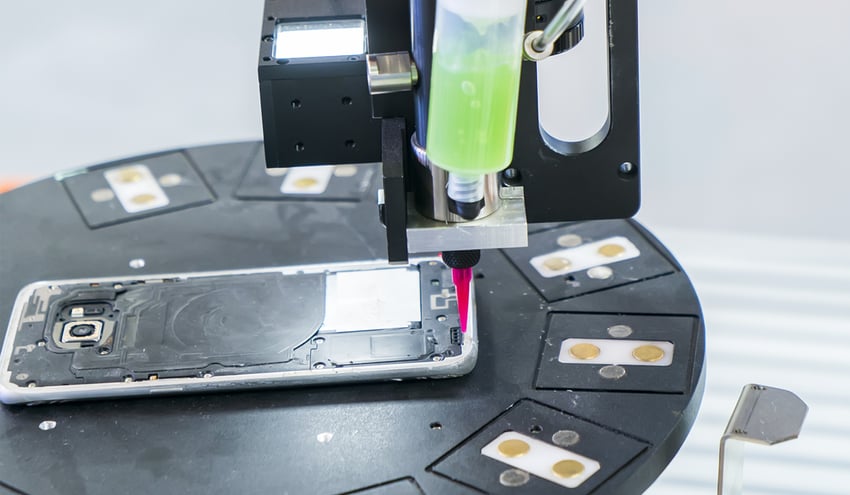

Tip #2: Control the Composition of the Adhesive

This (as well as tip #3) is something most manufacturers are adept at and usually look to first when trying to fix an adhesion issue. There is certainly logic to the thinking that if something isn’t sticking, you should get a better glue. However, this is only part of the story. In order to know for certain that a new glue is superior, there needs to be an understanding of how this adhesive is interacting with the top few molecular layers of the material surface. Controlling the relationship between the elements involved in the adhesion operation and not merely the elements themselves is imperative.

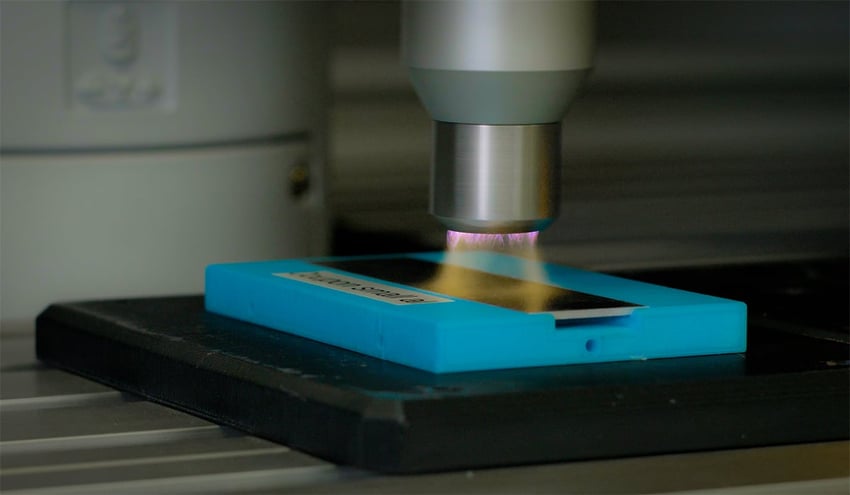

Tip #3: Control the Curing and Finishing

The curing and finishing steps that take place immediately after bonding or coating are crucial to the overall success of the process. Much like tip #2, this is an area that gets a lot of attention and energy from Quality Managers and Engineers. These curing and finishing processes can only do their job if the first two tips are managed and optimized. Curing an imperfect bond cannot make up for imperfections that weren’t handled to begin with.

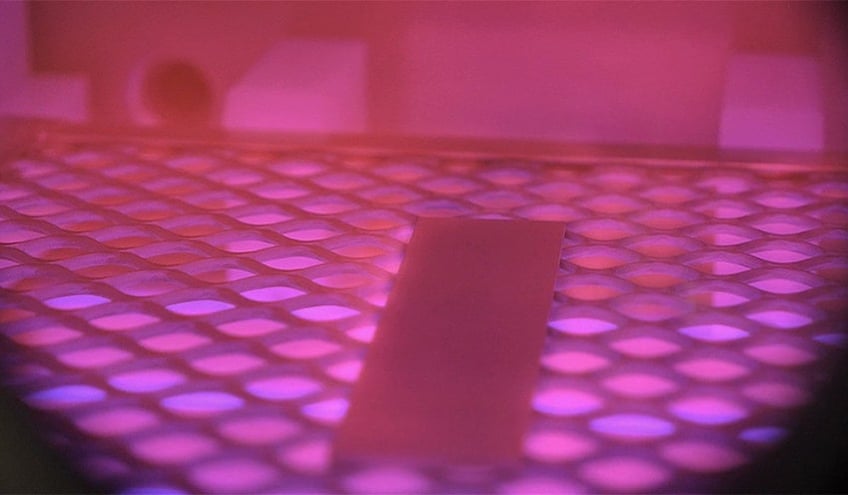

Tip #4: Control the Surface

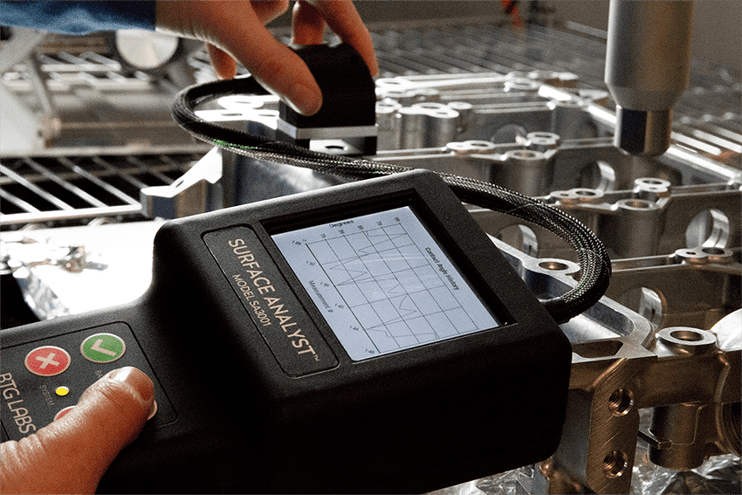

This is the most essential step that can be taken toward eradicating adhesion failure. This is also one of the most overlooked places to inspect when trying to find the root cause of adhesion problems or their solutions. The surface is not merely the material surface you can see. The top few molecular layers and what those layers are chemically comprised of have a tremendous effect on whether anything will stick to that surface. Fundamentally, adhesion is a chemical reaction between the top layers of molecules and the adhesive or coating. If the material surface is not chemically clean and functional, meeting the requirements for proper adhesion at a chemical level, the adhesion will not work. Since this is an invisible interaction (invisible to the human eye), control of those molecular layers is not as obvious as other aspects of the manufacturing process. Control needs to include a quantitative evaluation of the material surface and a method to manage that surface in order to get it to a state ready to be adhered to. Management of the surface requires an understanding of how the chemical state of the surface affects adhesion so that all the prior preparation steps are appropriate and effective.

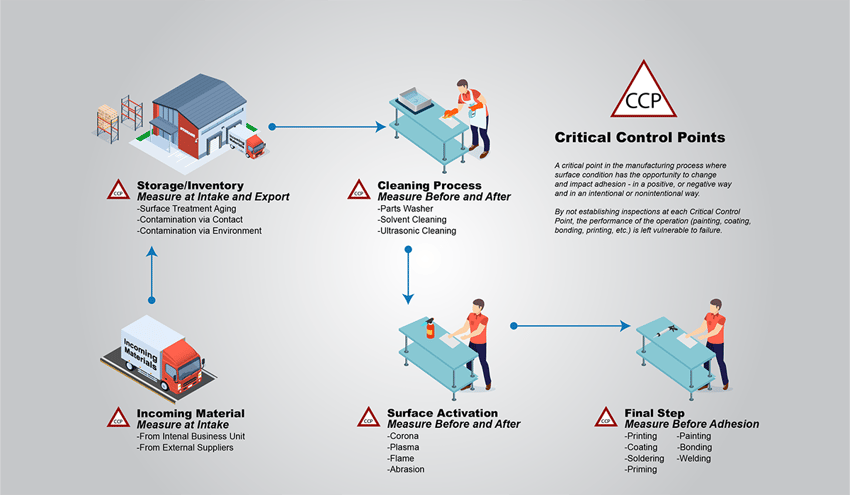

Tip #5: Inspect Each Critical Step of the Adhesion Process

Measurements and inspections need to be done every time a surface is interacted with in any way that intentionally or unintentionally changes that surface for better or worse. Likewise, there needs to be a baseline established for all materials that come onto a factory floor and into the adhesion process. Quantifying surfaces and adhesives when they are introduced ensures that the proper treatment and preparation will be applied. Over and under-treatment are serious causes of adhesion failure. This can be easily mitigated by inspecting surfaces at each step of the process so that control of cleaning and treatment procedures can be maintained.

Tip #6: Monitor and Optimize

Once all of these standards and quantifiable metrics are in place, there is still plenty more to do. Keeping a watchful eye on how close the standards are being met is critical to spotting trends drifting away from or back to the desirable thresholds. Using the data provided by the monitoring process allows manufacturers to fully optimize processes such as surface treatment and cleaning steps to save money and build a more efficient production system. There’s no need to fluctuate between extremes of repeated adhesion failure and mysterious success, having no insight into what changes led to these results.

Tip #7: Work with Surface Experts

All of these tips boil down to re-evaluating what adhesion success is and how it is achieved. Most manufacturers are not equipped to implement the kind of inspections or parameters necessary to ensure successful adhesion. Seek expert help. Learn what is happening on the surfaces of your materials and how that makes or breaks your bonds.

Struggling with adhesion failures? Been there. Solved that.

Manufacturers can’t and shouldn’t go it alone when trying to fix adhesion problems from the source. These seven tips all point to that fact. If something cannot be measured, then it cannot be managed. Find a material surface expert to help establish these new norms for an existing production line or one that is still in the planning stages.

Download the ebook "The Future of Manufacturing: A Guide to Intelligent Adhesive Bonding Technologies & Methodologies" for information on optimizing your adhesion process.