A Handheld Solution for Verifying Surface Cleanliness

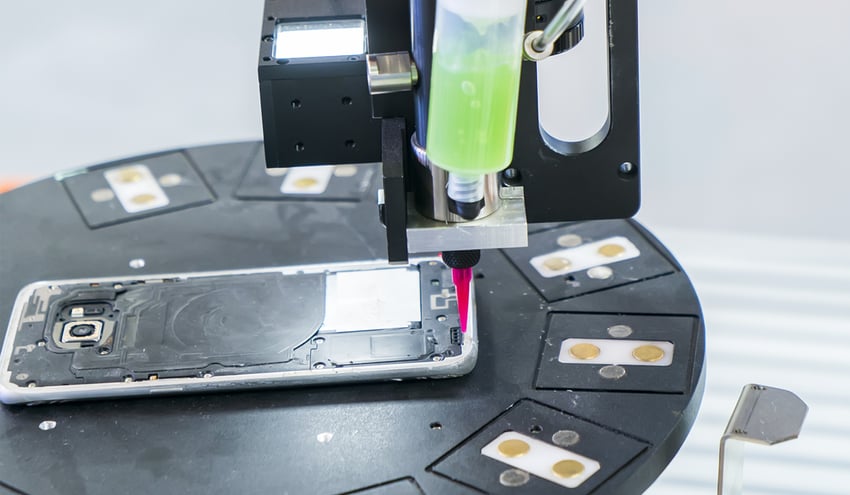

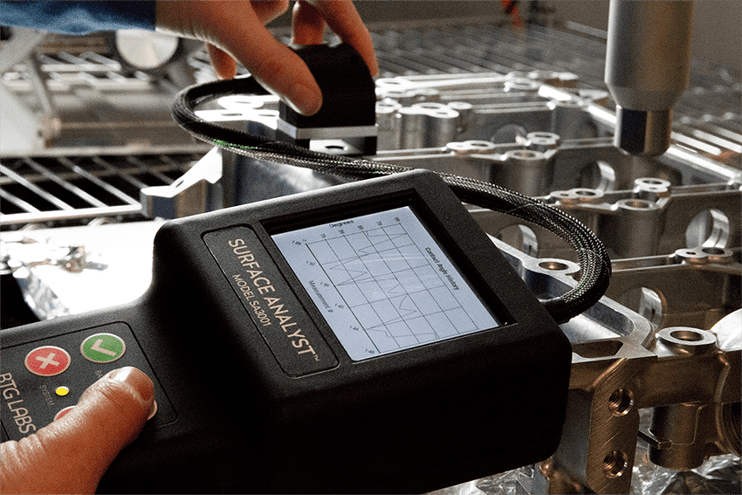

The Surface Analyst™ is an innovative handheld solution for use in the lab and on the factory floor. It reduces waste, rework, and recalls when poorly prepared substrate surfaces lead to bonding, coating, sealing, painting, or printing failure.

Using contact angle measurement, the Surface Analyst measures the cleanliness level of surfaces and determines how ready it is to accept the adhesive, coating, print, or paint. Developed and manufactured by Brighton Science, it is a fast, easy, accurate, and non-destructive tool for manufacturers with critical surface requirements. The Surface Analyst replaces legacy methods such as dyne and water break tests.

|

|

Figure 1: A water drop "wetting out," demonstrating a low contact angle and a clean surface. |

|

|

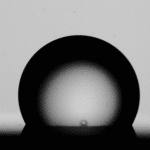

Figure 2: A water drop beading up, demonstrating a high contact angle and a contaminated surface. |

Rethink your adhesion manufacturing processes with Surface Intelligence.

Measuring Contact Angle to Determine Surface Cleanliness

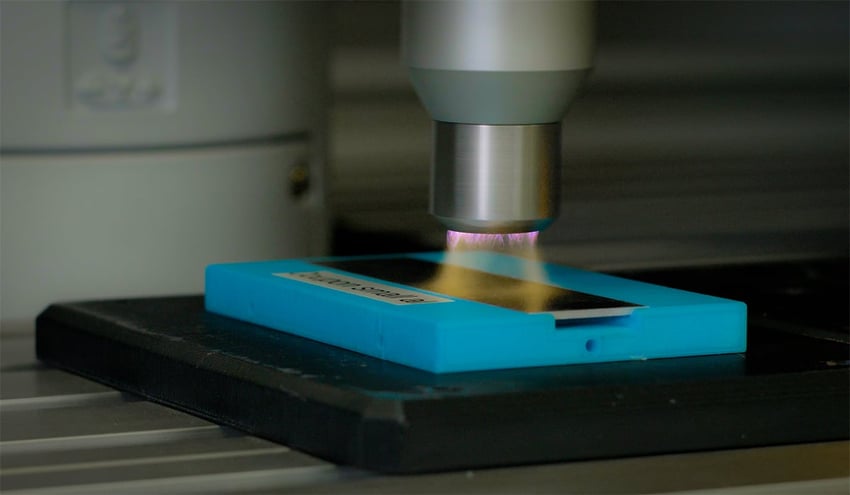

The Surface Analyst deposits a highly purified drop of water on the surface. In two seconds, it measures the contact angle and, in turn, determines the cleanliness level of a substrate.

When a surface is clean, it emits high energy, and water--as a high-energy molecule--spreads out on the surface in attraction to other high-energy molecules (Figure 1). A contaminated surface emits low energy and will cause water to bead up in attraction to itself rather than the low-energy surface molecules (Figure 2).

By knowing the volume and area of a drop of water, the contact angle of the water against a given surface can be determined. The larger the contact angle, the more the water beads up on the surface – and, therefore, the lower the energy level of the surface.

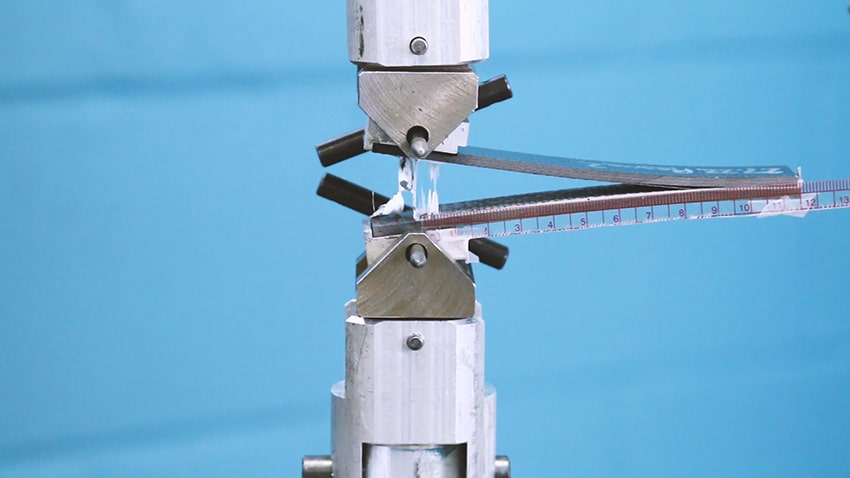

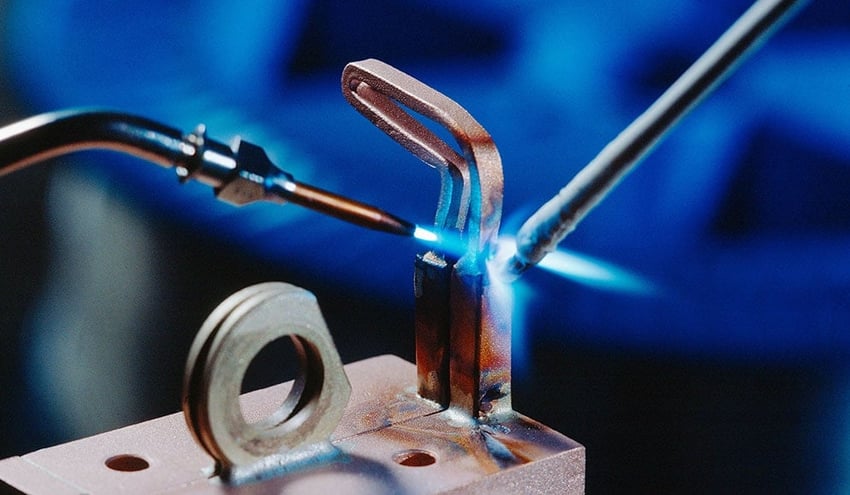

Ensuring a Contaminant Free Surface and a Strong Bond

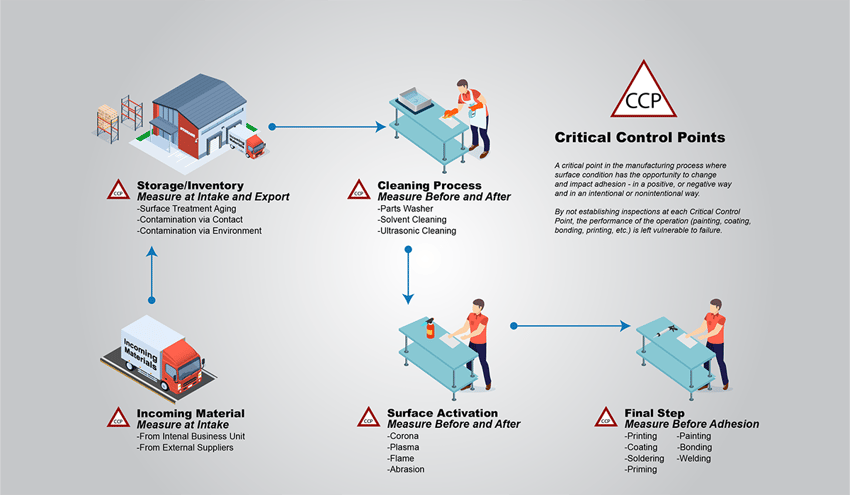

When adhering, the surface requires a level of cleanliness in order to produce strong, reliable bonds. Ensuring surface condition and consistency is vital for guaranteeing success in sealing, coating, bonding, painting, printing, or cleaning. All surfaces contaminate upon exposure, and the presence of contaminants is inevitable. However, studying and comprehending the relationship between a contaminant structure and the effects it can have on a bond can help develop more productive monitoring procedures for surface preparation processes and can also impact the development of stronger adhesives and coating formulations.

Outdated evaluation methods such as dyne and water break are destructive and do not provide reliable, precise, quantifiable surface measurements. The Surface Analyst exemplifies these traits on the factory floor in seconds.

Revolutionize Your Manufacturing with Surface Quality Inspection Technology.

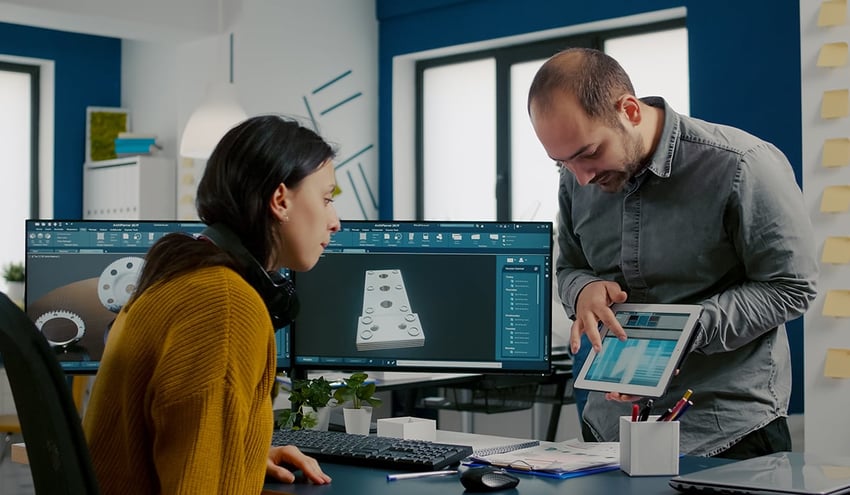

Brighton Science (formerly BTG Labs), a Materials Science-based technology company, focuses on understanding, quantifying, and controlling surface critical processes in manufacturing. Brighton Science has developed a versatile Surface Analyst technology suite widely used in the aerospace, automotive, electronic, medical device, and consumer product industries.

To learn how your business can leverage surface intelligence and contact angle data to innovate, optimize, and solve problems, download our free eBook, "The Future of Manufacturing: A Guide to Intelligent Adhesive Bonding Technologies & Methodologies."