Protective coverings are part and parcel of our lives these days. For industries reliant upon electronic components and connectors, protective coverings in the form of polymeric over-molding encapsulation need to remain sealed and impervious to the environment.

To accomplish this, manufacturers of over-molded cabling and electronic components must guarantee that their materials are clean enough for the covering to completely adhere with uniform strength. Clean is the operative word.

Overmolding is a rubber, silicone, or other polymer coating that is applied over the top of another material (think about the soft, pliable plastic wrapped around the more rigid handle of a toothbrush), often fully enclosing the interior material. The coatings can be applied through an injection mold process or a low-pressure molding technique.

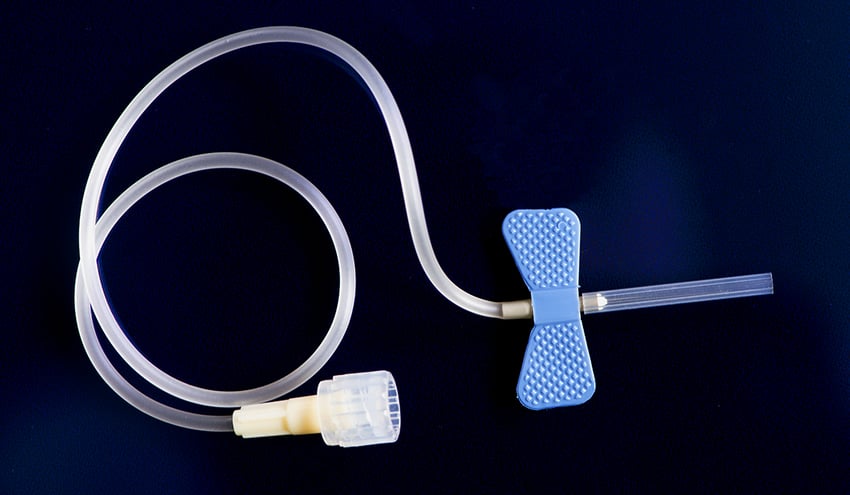

The idea is to keep electronics and critical components fully encapsulated and safe from hazards in the environment where the final product will be used. This can be a hospital room where an endoscopy camera is connected to cables running to a monitor to make sure the doctors aren't flying blind when inserting the device. Or a ventilator with several electronic connectors that absolutely must work consistently so the machines they help operate can run without interruption. Overmolding is also commonly used to protect cables in the complex electronic assemblies within aircraft and cars, which is only increasing each year.

For manufacturers building these machines, it’s imperative that they are able to control the cleanliness of the surfaces of cables, circuit boards, and other critical materials that are over-molded so the coating can do its job. Control of these processes requires the proper surface treatment and verification that the surfaces are being cleaned and treated effectively.

Rethink your adhesion manufacturing processes with Surface Intelligence.

What is the Over-molding Process

There are a couple of ways that over-molding is done. An over-mold can be created through an injection process where the connector or component is placed into a mold where a polymer covering is infused through an opening in the mold. The polymer covers the cables and parts completely and is then cured. Injection molding is similar to electronics potting, where a polymer is poured or deposited through a syringe-type device into and over components as a way of completely sealing them in.

To learn more about how to understand and control your adhesion process, download our eBook about detecting adhesion issues sources: Checklist: Adhesion Failure Root-Cause Analysis for Manufacturers

Another way of creating this polymer casing is through a process called low-pressure molding. This process begins with the bare component or cabling being placed in the lower half of a mold and then the upper half of the mold enclosing around the part. The cavity that is created by the two halves of the mold is filled with a thermoplastic with low viscosity, so it gently surrounds the electronics that might be vulnerable to somewhat more aggressive potting and injection molding techniques.

For any of these methods to work the way they're designed to, the surfaces of the materials being encased must be cleaned and treated to give the coatings the longest life possible. If the coating is uneven or begins to peel away from the surface of the electronics and connectors, then all of the protective qualities of the over-molding are totally compromised.

How to Protect Your Overmolding Before it is Even Applied

It’s important to know the materials you're using in your products. With over-molding, the thermoplastic elastomers (TPE), thermoplastic polyurethane (TPU), silicones, and other materials used are often chosen for their resistant qualities: UV resistance, flexibility without sacrificing strength, temperature resilience, etc. Typically, these are being adhered to dissimilar materials that need to be cleaned and have their surfaces chemically modified in some way to make sure the coating is complete.

A typical process for this might be a metal connector that needs to be encapsulated. The metal might be cleaned with a vapor degreaser or solvent wiping, a manual abrasion step, or perhaps an adhesion-boosting primer will be applied to the connector. After cleaning, the part might be put into inventory in a storage bag, all before actually being over-molded. For populated circuit boards, the process will likely include a plasma treatment step.

Within that cleaning and treatment process, there are several variables that, if left up to chance, might not provide the results manufacturers need.

Building predictability into this adhesion process requires control over two overarching aspects of the process. The supply chain of the components must be controlled, making sure that cleanliness requirements are being met from the outset. And control over the changes to the surface happening at each and every one of the cleaning and treatment steps outlined above (as well as any others that might be taking place) is crucial to a consistent process.

It can sound like an oversimplification, but if you can effectively manage these two things, then you are well ahead of the curve in creating over-molding bonds that will meet or exceed your expectations every time. The introduction of parts into your facility and the lifecycle of the surfaces of those parts within your facility are the two primary means of control over an adhesion process manufacturers have.

Every one of the places in the adhesion process where the surfaces of the materials change or have the opportunity to change to either create a more bondable or less bondable surface is called a Critical Control Point. These are the make-or-break points that allow manufacturers to gain the certainty they crave.

The rework of a connector or electronic component with a faulty over-molding is extremely costly in that; if there is a leak, the entire instrument is wasted. The coverings need to be completely impervious to their environments and able to withstand constant use over a long period of time. These hardworking components and over molds need to be ensured a long life by quantitatively inspecting the quality (read: cleanliness and bondability) of the surface all the way through the process. If there is an excess step (perhaps the manual abrasion is unnecessary and is merely a stopgap for an insufficient step upstream) or a contaminant being introduced during storage, the manufacturer can narrow down what’s working properly and what isn’t with systemic, data-driven monitoring of cleanliness.

This kind of root cause analysis can be done by manufacturers with the help of Adhesion Process Experts and a surface analysis system that is sensitive to the; sometimes subtle chemical changes surfaces go through.

Optimize the power of next-gen connectivity with data & surface intelligence.

When materials are cleaned and treated with vapor degreasers, primers, or plasma, the chemical composition of the surface changes to make a more reactive surface. This reactivity creates strong chemical bonds between the surface and the polymer coating. Measuring surface reactivity as a way to measure the readiness of a surface for over-molding means you can make decisions about your adhesion process based on the most precise variables affecting your bonding outcomes. You can know what steps are making your surfaces more bondable, which ones might not be useful in the ways you thought, you can know if you’re preserving your bondable surface during storage or degrading it, and to what extent, if you have a way of measuring these changes.

To learn how understanding and controlling your adhesion process will lead to strong, reliable bonds for over-molding and other coating and encapsulation processes, download our eBook about how to create a production process that produces the highest quality medical products. Whether you’re implementing over-molding into your production for the first time or have been experiencing issues with your coatings, the steps outlined in this guide will help you build certainty into your manufacturing process. Download your free copy today: How to Streamline Process Design to Production for Medical Devices.