Speed vs. Quality: How Manufacturing Sectors Balance Risk, Cost, and Innovation

In every manufacturing environment, there's one constant tension: how to move fast without breaking things. Whether you're building airplanes, cars, consumer electronics, or medical devices, the same tradeoff exists: production speed versus product quality.

Read

Topics:

Posts by Topic

Beyond Surface Prep: How Manufacturers Are Using Water Contact Angle to Control Adhesion Quality

Introduction Adhesion failures are among the most common yet preventable issues in composite bonding, coatings, and sealants. Whether in aerospace, automotive, or medical manufacturing, poor surface preparation can lead to structural weaknesses, warranty claims, and costly rework. But what if the...

Read

Topics:

Driving Change: Why Surface Quality in Automotive Manufacturing Demands Attention—and Action

The Hidden Factor in Automotive Reliability Every joint, seal, and coating in automotive manufacturing plays a crucial role in performance, aesthetics, and, most importantly, safety. Yet, one fundamental factor that determines whether these elements succeed or fail is often overlooked: surface...

Read

Topics:

Enhancing Automotive Manufacturing with Surface Intelligence

The Evolution of Automotive Materials and Their Challenges The automotive industry is constantly evolving, with manufacturers adopting advanced materials to improve strength, fuel efficiency, and durability while reducing weight and cost. Traditional materials like steel and iron are increasingly...

Read

Topics:

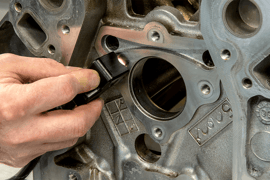

Ensuring Gasket Reliability: The Critical Role of Surface Quality in Formed-in-Place Gasket Applications

Formed-in-place gaskets (FIPG) have revolutionized sealing solutions across industries that require high-reliability seals. While there are many types of gaskets, a FIPG is created from a specific method where a liquid sealant, typically applied by an automated dispensing system, is dispensed...

Read

Topics:

What Automotive Manufacturers Need to Know About Surface Analysis for Polymer Bonding and Coating

Polymers have taken center stage in automotive manufacturing. Their light weight, durability, and versatility make them ideal for many applications ranging from dashboards and door panels to bumper facias and fenders. However, as any product development or quality control professional will tell...

Read

Topics:

Environmental Silicone: Detection, Control, and Impact on Adhesion in Manufacturing

Silicone contamination is a huge problem in many painting and bonding applications. It’s impossible to see, hard to remove, and it creeps in unseen like a ghost. Where the harm it can cause is recognized, businesses go to great lengths to clean surfaces and exclude potential sources of...

Read

Topics:

The High Cost of Molding Defects: Protect Your Bottom Line

Imagine crafting a colossal mold, a behemoth capable of shaping fiberglass and composites into the intricate contours of a plane wing, the sleek hull of a boat, or even the entire body of a bus. It's a monumental task, requiring months of meticulous preparation and planning. As you gear up to start...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Navigating the Solvent Switch: A Sustainable Future for Parts Cleaning

Manufacturers who use solvent-based industrial parts cleaning processes must find alternative methods. Solvent-based cleaning processes use chemicals that emit or release Volatile Organic Compounds (VOCs). These are coming under increased scrutiny due to their harmful effects on health and the...

Read

Topics:

4 Common Factors that Impact Conformal Coating Adhesion

The widespread use of electronics in all manufacturing sectors has presented distinct difficulties. Manufacturers are responsible for safeguarding these electronic devices in harsh conditions that render electronics susceptible to even the slightest traces of moisture, particles, and environmental ...

Read

Topics:

Adhesive Bonding vs. Mechanical Fastening in Product Design: The Pros and Cons

When creating their next innovative product, designers, and manufacturers strive to achieve optimal performance while minimizing assembly and materials costs. In this pursuit, they often focus on optimizing material usage. In the quest to achieve optimization, it is uncommon for excess materials to...

Read

Topics:

The Best Way to Qualify a Wash Method for Your Manufacturing Process

Parts washers are heavy-duty, hardworking machines that have become irreplaceable staples in automotive andmachined part manufacturing processes. As manufacturing processes have become more sophisticated, the industries using parts washers have expanded to includenot only industrial metals and...

Read

Topics:

Why Automotive Glass Bonding Recalls Should be a Thing of the Past

Automotive glass is a technological marvel. Despite its clarity, much of how it's manufactured is unseen by the average driver. Silica compounds, tempering, and lamination all combine to create one of the most critical components of today’s motor vehicles. Unfortunately, though, things periodically...

Read

Topics:

Top Challenges Product Development Teams Experience When Bringing a Product Concept to Manufacturing

Modern product development is fraught with challenges due in large part to the sophistication and complexity of the various elements that go into a final product – everything from materials and surface geometries to coatings, bonding, and even staff skills and competencies. Pitfalls await even the...

Read

Topics:

3 Things You Need to Know to Create Strong, Reliable Bonds With Laser Cleaning

Manufacturers are always looking to create stronger, more durable, reliable, and lightweight products in the automotive and aerospace sectors. In this pursuit, they’ve often upgraded and swapped out material systems for metal alloys with lower density, better temperature tolerance, and corrosion...

Read

Topics:

How to Avoid Polymeric Coating Failure Which Leads to Corrosion in Materials

These days, if you see a painted product, it is likely a polymer-based coating providing a striking and powerful barrier between the underlying material and elements in the atmosphere that want to corrode that material. Polymer coating technology has advanced tremendously in the last decade....

Read

Topics:

Effective Strategies for Efficient and Reliable Manufacturing That Can’t Wait

Today, manufacturing requires a paradigm shift from reactionary whack-a-mole problem correction to taking a holistic approach. The mutually reliant elements of manufacturing are interwoven in both obvious and invisible ways. From supply chain communication to equipment dependability and from ...

Read

Topics:

How to Get a Stronger Weld Through Cleaning

Even though we look around us and see plastic everywhere, in every shape and imaginable application, metals are still a more commonly used raw material in machined products. Metals are the legacy material of choice due to their strength and relative ease of bonding. However, advances in polymers...

Read

Topics:

Coatings on Car Sensors and Why We Don’t Have Driverless Cars Yet

Our relationship with our vehicles may have changed in the past few months, with the idea of commuting to work looking more like a shuffle to the desk across the room rather than a drive to the office across town. However, cars have not dropped in prominence in our society. With health risks now...

Read

Topics:

Demystifying the Greatest Metal Brazing Process Challenges

When thinking about what manufacturing looks like, most people envision sparks flying, metal clanking, and fires blazing. This isn’t too far off the mark since metals were used to bond joints together to build larger, sturdier, and more stable structures before the first Industrial Revolution,...

Read

Topics:

Importance of Adhesion & Composites in Lightweighting Cars

One of the most pressing questions on the minds of manufacturing engineers is how to take a load off. Lightweighting, or shedding pounds on assembled vehicles and machinery, is a critical puzzle in aerospace, marine, and, most acutely, automotive industries. In fact, with the pressure to optimize...

Read

Topics:

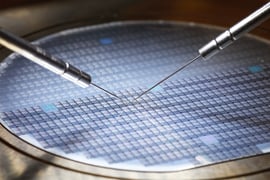

Don’t Forget the Surface of Microelectronics

It’s easy to be dazzled by the advancements in electronic and medical devices that are constantly being made and discovered, allowing manufacturers to work on increasingly micro levels. Smaller tech means greater efficiency and higher production rates, which can lead to lower prices and more...

Read

Topics:

Guaranteeing Anti-fog Coating Application on Automotive Headlights

The competitive nature of the automotive industry requires manufacturers to engineer the ideal product; failures, no matter how small, are unacceptable and can bring heavy consequences.

Read

Topics:

Optimizing your Metal Performance with the Surface Analyst

Manufacturers who work with metal and are concerned with metal performance are all too familiar with the obstacles that come along with coating, painting, bonding, printing, or sealing it. While the uses of metal in manufacturing are countless and exist in numerous industries, the common...

Read

Topics:

Automotive Series: Surface Preparation of Composite Surfaces

Building a More Fuel-Efficient Automobile The pursuit of producing a more fuel-efficient automobile does not rely solely on the efficiency of the engine. A great amount of fuel efficiency gains are possible not because of improvements to engine design but because of improvements in materials....

Read

Topics:

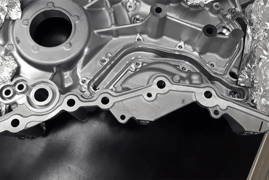

Contact Angle Analysis: Sealing Surface of Aluminum Castings

Surface Quality Requirements of Aluminum Castings Automotive manufacturers widely utilize aluminum castings as the most successful way to create aluminum parts. However, this process can involve inorganic contaminants on the surface, which interfere with potential bonding, sealing, or coating....

Read

Topics:

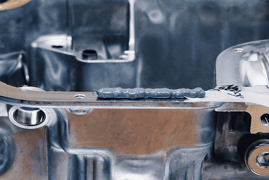

Automotive Applications Series: Ensuring Success for Formed-In-Place Gasket (FIPG) Applications

Controlling Surface Condition in FIPG Application Increasingly, FIPG processes are replacing traditional gaskets for a variety of automotive applications, such as air filters, oil filters, door panels, and external engine parts. The advantages include cheaper material cost, higher throughput...

Read

Topics: