Bridging the Gap Between Data and Action in Manufacturing with BConnect

In the last decade, industries have increasingly recognized the importance of surface readiness as a critical factor in bonding processes. Yet, this understanding often fails to permeate every level of the organization, particularly among personnel directly working on manufacturing lines. Whether...

Read

Topics:

Posts by Topic

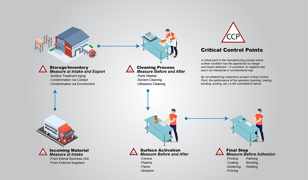

Managing Critical Control Points and Adhesion Failures with Next-Gen Technology

Bond failures remain a significant challenge for manufacturers, occurring on a large scale every week despite widespread awareness of the importance of surface readiness in bonding processes like sealing, coating, cleaning, and painting. Why? Because controlling adhesion throughout every...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

5 New Ideas to Address Common Challenges Manufacturing Plant Managers Face

Leadership of a manufacturing plant demands exceptional skill. Plant managers navigate a dynamic landscape of ever-evolving responsibilities. Drawing on a decade of collaboration with hundreds of companies across countless operational challenges, we've identified key insights to help tackle these...

Read

Topics:

Revolutionizing Multi-Site Manufacturing: Unleashing Operational Excellence Through Standardized Surface Quality Measurement

Are inconsistencies in bonding between your multi-site manufacturing lines creating poor-quality parts, like a band singing out of tune? This article will help you to identify and resolve those issues for good. Discover what causes inconsistent bonding, learn how to manage it, and get your...

Read

Topics:

Contact Angle Goniometer 101: A Guide to Successfully Measuring Contact Angle

Have you wondered why some paints or coatings adhere effortlessly while others leave blisters or bubbles? The answer lies in wettability, the intricate dance between a liquid and a surface governed by a powerful principle known as contact angle. And measuring this microscopic tango? That's where...

Read

Topics:

How to Control Your Adhesive Process: Find the Critical Control Points

In today's highly competitive manufacturing environment, controlling the adhesive process is vital to ensuring product quality, consistency, and efficiency. Understanding the Critical Control Points (CCPs) within the adhesive process is essential for maintaining control and achieving desired...

Read

Topics:

The Thought Behind our New Brighton Academy

Over the past decade, we have been told that our science is the cornerstone of our customer relationships. Whether you’ve been with us from the beginning or just recently joined the BConnect community, during your journey with us, we’ve likely shared our scientific insights with you. This may have...

Read

Topics:

How to Propel Enterprise Success through Effective Knowledge Sharing of Bonding Processes

Wind turbines have a problem: their giant blades fail more often than anticipated. Research on the issue, reported in the journal Materials, notes an average of 3,800 failures each year. Many of these result from adhesive bonding defects, which should be addressed and prevented through improved...

Read

Topics:

Surface Intelligence: A New Opportunity in Supply Chain Management

Water contact angle seems like an obscure technical curiosity, but what if we said it could help you improve profitability and win new business? Water contact angle provides information about surface energy, which tells you about the condition of a surface. This information is rarely used in the ...

Read

Topics:

The Hidden Costs of Human Choices: Compromising Optimal Product Design and Manufacturing

In the realm of manufacturing and production, achieving strong and durable bonds is crucial for ensuring the quality and reliability of products. However, even with meticulous adherence to established processes, companies can sometimes face unexpected challenges that hinder their bonding...

Read

Topics:

How to Enhance Your Real-Time Production Monitoring of Material Surface Quality

The globalization of supply chains, diversification of team locations, outsourcing of essential organizational functions, and the digitalization of data and communication have made the world accessible to small and medium-sized manufacturers, challenging both large and small enterprises to respond...

Read

Topics:

Fail Early, Fail Often: How Predictive Modeling Allows Teams To Quickly Assess And Correct Adhesion Failure In Product Development

What Does 'Fail Fast, Fail Often, Fail Intelligently' Even Mean? When it comes to business and innovation, making mistakes is inevitable. But instead of shying away from failure, we should embrace it as an opportunity to learn and grow. This concept is often referred to as "fail fast, fail often,...

Read

Topics:

Why You Should Use Predictive Data in Building Material Manufacturing

The building industry relies heavily on adhesives and coatings to ensure structures are weatherproof, durable, and aesthetically pleasing. From modern flooring to sturdy roofs, these building materials rely on a strong bond – both literally and figuratively. However, unlike many other industries,...

Read

Topics:

Launch Faster and Smarter: How to Streamline New Product Development with Surface Intelligence

As an increasing number of manufacturers adopt the fundamental principles of Industry 4.0, they are reaping the rewards of its key concepts. These include the integration of systems and processes, information transparency, and the commercialization of smart technology. This, in turn, promotes a...

Read

Topics:

What is Materials Science & Why is it Crucial for New Product Development?

Many people are not familiar with the subject matter and discipline of materials science because it’s not taught in elementary or high school and only infrequently at the university level. Instead, we are often taught chemistry and physics. Chemistry teaches us how atoms and molecules interact,...

Read

Topics:

Are You Ready for Zero Defect Manufacturing? Discover the Top Industry 4.0 Strategies

It's important to recognize that assuming control over the future based on past or present circumstances is a common misconception. The events of 2020 have taught us a valuable lesson - we should never be overconfident enough to believe that we can predict the challenges that lay ahead.Furthermore,...

Read

Topics:

Accelerate Your Digital Transformation: Why SaaS is the Fastest Path to Success

Business operations change daily, if not more frequently. While some businesses are content working inside a structure that hasn’t been updated for 20 years, others are looking to optimize their digital transformation strategies to match the digitalization of the twenty-first century. “The biggest...

Read

Topics:

The Relationship Between Total Quality Management Systems and Sustainability

In the age of sustainability practices becoming more of the norm, there are a few ways in which your company can both abide by new regulatory standards concerning sustainable changes to the chemicals used and have a positive impact on your total quality management standards.

Read

Topics:

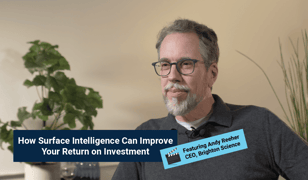

How Surface Intelligence Can Improve Your Return on Investment

“For every company, its competitiveness comes from its ability to assimilate knowledge and failure - which I tell my kids all the time - failure is an opportunity to learn and feedback is a gift. And if we take the 'quick fix' we take the learning off the table.” Andy Reeher, CEO, Brighton Science

Read

Topics:

How To Keep Up With the Changing Landscape of Advanced Materials

There's a logical fallacy akin to a "what's good for one is good for all" mindset that is devastating when applied to surface treatment in adhesion processes. Polymers are rapidly being developed and synthesized for niche applications to push the limits of the current physical properties of...

Read

Topics:

Why Your Business Should Reject a Culture of 'Quick Fixes'

Quality gurus have long preached the importance of getting to the root of the problem. So why, then, when managers understand this so well, do organizations settle for the quick fix? It’s like taking a painkiller for a headache: the pain goes away for a while, but if there’s an underlying cause,...

Read

Topics:

What Does Surface Intelligence Look Like in Action?

Surface condition is a significant driver of process and product reliability. It affects every part of the product life cycle, from development to launch, and its impact continues for as long as the product remains in service.

Read

Topics:

Top 6 Reasons Your Internal Organization Should Care About Surface Intelligence

Intelligence is a funny thing. On its face, it seems like the best way to gauge intelligence is to measure one's capacity for maximum knowledge intake through rote memorization of facts and figures. That sounds good, but it doesn't feel quite right. Because we all know knowledge that's just piled...

Read

Topics:

Boost New Product Innovation Using Materials Science and Technology

Having the freedom to design and build to the limits of our imaginations is at the core of what makes us human. You must think outside the common practice to boost innovation and improve processes to accomplish this task.

Read

Topics:

4 Critical Questions to Consider When Assessing Risks in New Product Development

There are numerous obstacles to achieving and then maintaining a clean material surface. But there is one element that carries through the entire product lifecycle and can have a massive impact on the adhesion performance of the final product: TIME.

Read

Topics:

Why Creating a Surface Intelligence Center of Excellence is Crucial for Manufacturing

As manufacturing becomes more complex and the globalization of supply chains increases, the need for a Surface Intelligence Center of Excellence grows. Such a center would compile data, training, and best practices from across the business to identify areas where further efficiency and quality...

Read

Topics:

How to Achieve Reliable Manufacturing by Controlling Surface Quality

When a material begins its journey through a manufacturing process, it becomes crucial to know and control everything that happens to that material as it makes its way down the line. There are two major factors to consider when understanding and controlling what happens to the surface of that...

Read

Topics:

How Surface Intelligence Enables Data-Driven Decision-Making & Advances Business Growth

Formula 1 teams know that you must incorporate a tried-and-true process into your workflow to perform at the highest level. They practice a defined, repeatable, measured, tested, and continuously improve their processes to ensure that their level of performance is constantly increasing. This can be...

Read

Topics:

What Is the Role of Surface Chemistry in Industry?

Manufacturing has become increasingly complex with the fusion of technologies that are blurring distinctions between the digital, physical, and biological worlds. Physical products and services have transformed significantly due to enhancements made possible by digital capabilities. New...

Read

Topics:

The Benefits of Benchmarking Surface Quality in Manufacturing

Certainty is the goal of every manufacturing process. Manufacturers must have total confidence that every aspect of their production process will go according to plan. The adhesion process needs to be controlled just like any other production operation, with accuracy and ongoing monitoring....

Read

Topics:

How to Quickly Qualify Suppliers and Make Changes with Confidence

Materials used to manufacture increasingly advanced and complex products have likewise evolved to be equally advanced and complex. As a result, it has become critical to understand the surfaces of these materials in order to optimize their ability to accept various paints, films, coatings, and...

Read

Topics:

Does Your Organization Take A Holistic Approach to Innovation?

Innovation can be a scary thing. For companies built on order, predictability, and success, innovation can be unsettling. It can be messy, unpredictable, and prone to failure before producing a demonstrable payback. But innovation is vital. Without it, there can be no evolutionary growth or...

Read

Topics:

How to Use Surface Intelligence Data to Build Smart Prototypes and Rapidly Pilot Manufacturing Lines

Since the Industrial Revolution, manufacturing has been evolving, periodically marked by significant, fundamental changes such as the introduction of mechanization, mass production through assembly lines, and computerization. Today, we are witnessing what experts call Industry 4.0 – a period when...

Read

Topics:

The Surface Analyst™ Instantly Measures Contact Angle to Determine the Potential Adhesive Strength of Bonds

A Handheld Solution for Verifying Surface Cleanliness The Surface Analyst™ is an innovative handheld solution for use in the lab and on the factory floor. It reduces waste, rework, and recalls when poorly prepared substrate surfaces lead to bonding, coating, sealing, painting, or printing failure.

Read

Topics:

Top Challenges Product Development Teams Experience When Bringing a Product Concept to Manufacturing

Modern product development is fraught with challenges due in large part to the sophistication and complexity of the various elements that go into a final product – everything from materials and surface geometries to coatings, bonding, and even staff skills and competencies. Pitfalls await even the...

Read

Topics:

BTG Labs evolves capabilities, leadership and name to become Brighton Science—bringing unmatched expertise to the emerging field of Surface Intelligence.

BTG Labs, a company that has spent the past 20 years solving critical adhesion issues and developing the world’s first surface inspection technology for leading manufacturers, has evolved its capabilities, leadership and name to become Brighton Science.

Read

Topics:

Why Manufacturers Can’t Achieve Manufacturing Innovation Gains by Simply Purchasing Equipment

Innovation is a word you hear tossed around frequently in various industries. Many organizations pursue innovation relentlessly as the key to their success and to gaining or maintaining a competitive edge. But innovation can be elusive for organizations that don’t quite know how to support it. As a...

Read

Topics:

Top 5 Trends in Products & Manufacturing Today

Change is perhaps the one absolute constant in manufacturing. Developments - in materials, processes, machinery, testing, products, markets, and thousands of other things affecting manufacturing companies - happen daily.

Read

Topics:

Eliminate Surface Engineering Challenges & Design with Freedom

Oftentimes, to boost innovation and improve processes, you have to think outside the common practice. You have to take the restraints off of creativity. Freedom to design and build to the limits of our imaginations is at the core of what makes us human.

Read

Topics:

Harnessing the Power of Water to Achieve Precise Results

Nature is miraculous. Living entities, be they plants, animals, marine life, or humans, can perform an amazing array of complex tasks. As scientists, inventors, and engineers, we take inspiration from any source that provides a good idea.

Read

Topics:

What is the Best Surface Quality Inspection for Smart Manufacturing?

Manufacturing processes can, on the surface, appear to be an amorphous web of convoluted conveyors and machinating machinery. But taking a closer look through the eyes of a quality engineer reveals that the process that leads to reliable products is, in fact, itself a series of decisions, each...

Read

Topics:

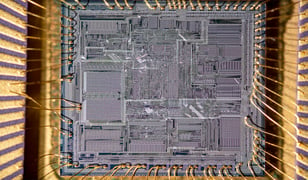

Reliable Wire Bonding Through Quality Data Collection for Industry 4.0

Wire bonding and sintering are critical processes involved in the manufacture of a majority of electronic devices. These processes are used to connect silicon chips, integrated circuits (ICs), and electrical components to their housings and boards.

Read

Topics:

Where to Look to Achieve Operational Visibility in Manufacturing

Enterprise manufacturing operations comprise interlocking, overlapping, and critically interdependent processes. Each process in this symbiotic web consists of a series of steps that are only successful when the invisible details are unshrouded and subject to quantitative quality parameters.

Read

Topics:

Ensuring the Durability of Oleophobic Coatings on Consumer Tech

Today, we're much more aware of the surfaces we touch and the potential unseen threats that linger on them. This focus on surface interaction isn't new for manufacturers, who've long considered how surfaces interact with our skin and the environment. Think about it – the simple act of touching...

Read

Topics:

COVID-19 Makes Remote Quality Monitoring Crucial for Manufacturers

Since COVID-19 has reshaped the economic landscape for the foreseeable future and there are many questions about how to safely and effectively respond to it, now is a good time for manufacturers to consider how to make the best of our “new normal” if they haven’t already done so in earnest.

Read

Topics: