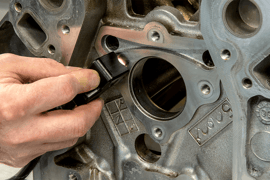

Ensuring Gasket Reliability: The Critical Role of Surface Quality in Formed-in-Place Gasket Applications

Formed-in-place gaskets (FIPG) have revolutionized sealing solutions across industries that require high-reliability seals. While there are many types of gaskets, a FIPG is created from a specific method where a liquid sealant, typically applied by an automated dispensing system, is dispensed...

Read

Topics:

Posts by Topic

Environmental Silicone: Detection, Control, and Impact on Adhesion in Manufacturing

Silicone contamination is a huge problem in many painting and bonding applications. It’s impossible to see, hard to remove, and it creeps in unseen like a ghost. Where the harm it can cause is recognized, businesses go to great lengths to clean surfaces and exclude potential sources of...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Navigating the Solvent Switch: A Sustainable Future for Parts Cleaning

Manufacturers who use solvent-based industrial parts cleaning processes must find alternative methods. Solvent-based cleaning processes use chemicals that emit or release Volatile Organic Compounds (VOCs). These are coming under increased scrutiny due to their harmful effects on health and the...

Read

Topics:

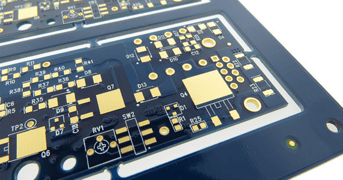

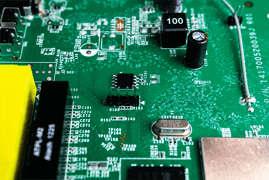

4 Common Factors that Impact Conformal Coating Adhesion

The widespread use of electronics in all manufacturing sectors has presented distinct difficulties. Manufacturers are responsible for safeguarding these electronic devices in harsh conditions that render electronics susceptible to even the slightest traces of moisture, particles, and environmental ...

Read

Topics:

Ensuring Top-Quality Solder Joints on ENIG PCBs: Best Practices Unveiled

The field of printed circuit board (PCB) finishing and bonding methods has been growing and diversifying for decades. PCB design depends heavily on the use and environment of the electronic package, and those design decisions include what Surface Mount Technology (SMT) is employed. SMT involves the...

Read

Topics:

Top Challenges Product Development Teams Experience When Bringing a Product Concept to Manufacturing

Modern product development is fraught with challenges due in large part to the sophistication and complexity of the various elements that go into a final product – everything from materials and surface geometries to coatings, bonding, and even staff skills and competencies. Pitfalls await even the...

Read

Topics:

Better Consumer Electronics Reliability: Coatings and Adhesives

In a recent study conducted by Instrumental, the top ten most common manufacturing defects were examined. The number one defect that manufacturers fight against is a deficiency in glue.

Read

Topics:

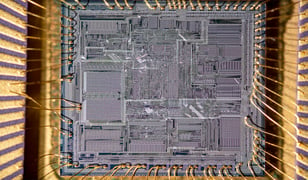

Reliable Wire Bonding Through Quality Data Collection for Industry 4.0

Wire bonding and sintering are critical processes involved in the manufacture of a majority of electronic devices. These processes are used to connect silicon chips, integrated circuits (ICs), and electrical components to their housings and boards.

Read

Topics:

Where to Look to Achieve Operational Visibility in Manufacturing

Enterprise manufacturing operations comprise interlocking, overlapping, and critically interdependent processes. Each process in this symbiotic web consists of a series of steps that are only successful when the invisible details are unshrouded and subject to quantitative quality parameters.

Read

Topics:

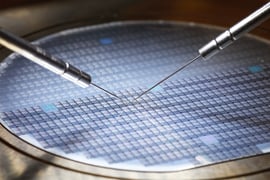

The Best Method of Controlling HMDS Use in Semiconductor Manufacturing

Semiconductors are one of the most fascinating areas of electronics manufacturing. The ability to “grow” almost irreducibly small integrated circuit components on silicon wafers has made an incredible amount of micronization possible. The theory has always been that as the chips got smaller, their...

Read

Topics:

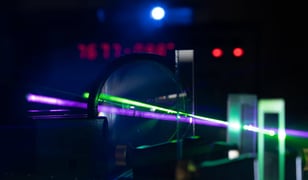

Surface Preparation for Reliable Optical Coatings in Photonics Manufacturing

Coatings are an indispensable part of manufacturing photonics. The coatings help determine the most basic functionality of the lenses they are applied to. How much light passes through, what happens to that light when it passes through the lens, does some light get absorbed, and are some spectral...

Read

Topics:

Ensuring the Durability of Oleophobic Coatings on Consumer Tech

Today, we're much more aware of the surfaces we touch and the potential unseen threats that linger on them. This focus on surface interaction isn't new for manufacturers, who've long considered how surfaces interact with our skin and the environment. Think about it – the simple act of touching...

Read

Topics:

Coatings on Car Sensors and Why We Don’t Have Driverless Cars Yet

Our relationship with our vehicles may have changed in the past few months, with the idea of commuting to work looking more like a shuffle to the desk across the room rather than a drive to the office across town. However, cars have not dropped in prominence in our society. With health risks now...

Read

Topics:

How to Get the Most Out of Your Vacuum Plasma Treatment

Vacuum plasma is the treatment method of record for many manufacturers. Not only because it is a legacy technology proven useful over many, many decades but because it can be particularly effective at creating chemically reactive surfaces of various geometries that need to be bonded, coated,...

Read

Topics:

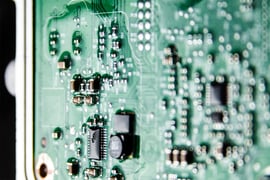

Plasma Treatment for Complete and Reliable Cleaning with Richard Burke

At IPC APEX 2020 in San Diego, we wanted to explore the ways that electronics manufacturers, who encapsulate their circuit boards with a conformal coating, are cleaning their boards. What are the benefits to their current processes, and what are some things manufacturers could learn to make their...

Read

Topics:

History of Cleaning for Ideal Electronics Manufacturing with Mike Konrad

At IPC APEX 2020 in San Diego, we got the chance to sit down and chat with Mike Konrad from Aqueous Technologies and the Reliability Matters podcast, a show about the reliability of circuit assemblies.

Read

Topics:

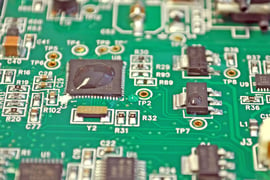

Why Surface Cleanliness is Crucial for Electronic PCBs

Defining “clean” is actually more complicated than it sounds. Cleanliness can be in the eye of the beholder (I mean, we all had a college roommate who swore they were tidy, but let’s be honest…), and it can also be calculated and precisely managed to the nth degree. In regard to PCB cleanliness for

Read

Topics:

Conformal Coating Failure Caused by Poor Surface Cleanliness

Electronic components consist of many exposed and delicate pieces that leave them vulnerable. A lot is relying on these fragile parts to function without fail. From implantable medical devices to navigational equipment and from sensor packages in cars to cell phones, the manufacturers of electronic...

Read

Topics:

Don’t Forget the Surface of Microelectronics

It’s easy to be dazzled by the advancements in electronic and medical devices that are constantly being made and discovered, allowing manufacturers to work on increasingly micro levels. Smaller tech means greater efficiency and higher production rates, which can lead to lower prices and more...

Read

Topics:

Optimizing your Metal Performance with the Surface Analyst

Manufacturers who work with metal and are concerned with metal performance are all too familiar with the obstacles that come along with coating, painting, bonding, printing, or sealing it. While the uses of metal in manufacturing are countless and exist in numerous industries, the common...

Read

Topics: