Bonding Composites: Confirming Surface Readiness with Reliable In-line Assessment

An aerospace spacecraft manufacturer uses the Handheld Surface Analyst 5001 to confirm surface readiness.

Read

Topics:

Posts by Topic

Optimizing Parts Washer Efficiency for FIPG

Competition is hot in the fast-paced automotive industry, and manufacturers work intensively to create more efficient, reliable vehicles. When the race is head-to-head, there is no room for failure. Finding ways to avoid failures and produce a more reliable vehicle provides a competitive edge.

Read

Topics:

Kala Adopts New Surface Quality Measurement Method for Better Vendor Compliance

Kala is a technological leader in flexible packaging finishing and printing and was built on the principle of continual improvement through process innovation. So when Kala had plans to improve bonds in a lamination program, they contacted Brighton Science to consult on the best ways to understand...

Read

Topics:

Identification of a Non-Obvious Contaminant on Polymer Film

A major packaging company was having intermittent problems heat sealing a film used to package paper products. Dyne pens, used to measure surface energy, showed no differences between a “good” film, one that heat sealed appropriately, and a “bad” film, one that did seal correctly.

Read

Topics:

Verifying Plasma Treatment on Medical Tubing Prior to Coating

Medical device manufacturing is a serious business. It’s a business that directly affects a person’s health and well-being. When a product operates so intimately with human life, there is no room for failure. The final product must be reliable and top-of-the-line to address patients’ needs...

Read

Topics:

Monitoring the Application of a Barrier Coating on the Inside of Paint Cans

Surface energy measurements have many obvious uses; however, some are not so straightforward. A manufacturer of high-quality consumer paint containers who prides itself on being meticulous with its product quality desired to refine its existing surface energy measurement processes. The company...

Read

Topics:

When the Success of a Bond Influences a Life: Prosthetic Attachment

Ensuring a bond will hold is the most important component of adhesion. At times, a successful bond could change a life.

Read

Topics:

Window Manufacturers Evolve from Dyne Inks to the Surface Analyst

Verification of surface treatment processes is necessary to ensure a successful product. A window and door manufacturer was using dyne pens to verify their plasma treatment on vinyl prior to bonding. However, the manufacturer was not happy with dyne as it was messy, destructive to the part being...

Read

Topics:

Determining the Sweet Spot of Flame Treatment in Automotive Interior Parts

In 2014, a large manufacturer of automotive exteriors and interiors encountered a problem consistently adhering paint to their dashboards due to inappropriate use of their flame treatment.

Read

Topics:

Supplier Quality Assurance for Circuit Board Printing

Supplier quality can be a major concern to an OEM. Questions arise: What specifications pertain to the supplier to ensure reliable products? How can OEMs guarantee the supplier is accurately sending what is needed? What supplier quality checks should OEMs put in place? Communicable specifications,...

Read

Topics:

Ensuring Successful RTV Sealing in Automotive Engines

Room Temperature Vulcanizing (RTV) adhesives brag several benefits over traditional gaskets, including cost-effectiveness and faster and easier application. However, RTV silicone does not perform well with hydrocarbons which are highly inevitable in the automotive industry. When RTV is replacing...

Read

Topics:

Verifying and Monitoring Surface Preparation Processes of Golf Club Manufacturing

Having an efficient surface preparation process is key. But what do you do when that process no longer produces the desired results? How do you verify the success of your surface preparation process?

Read

Topics:

Reevaluating the Assembly Process of Failing Oil Filters

When manufacturers supply products to customers, they want to have the highest confidence in the quality of those products. But, when proper measures aren't accessible or available to guarantee quality, a major need arises.

Read

Topics:

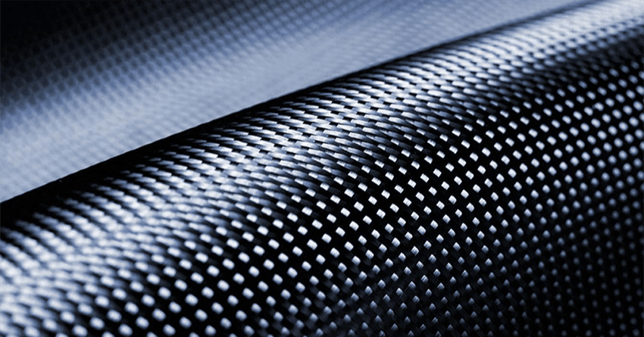

Verifying Multi-Step Surface Preparation Processes in Aircraft Assembly and Repair

The surface preparation processes used to assemble or repair an aircraft include multiple steps to achieve a final bond. For a strong, safe, and effective bond, all steps in the process must be consistent and validated prior to moving forward in the process.

Read

Topics:

Incoming: Validating Supplier Materials for Solar Panel Manufacturing

When manufacturers experience difficulties relating to product quality, it's common to believe the issue to be internal, and this is sometimes the case.

Read

Topics: