Industries

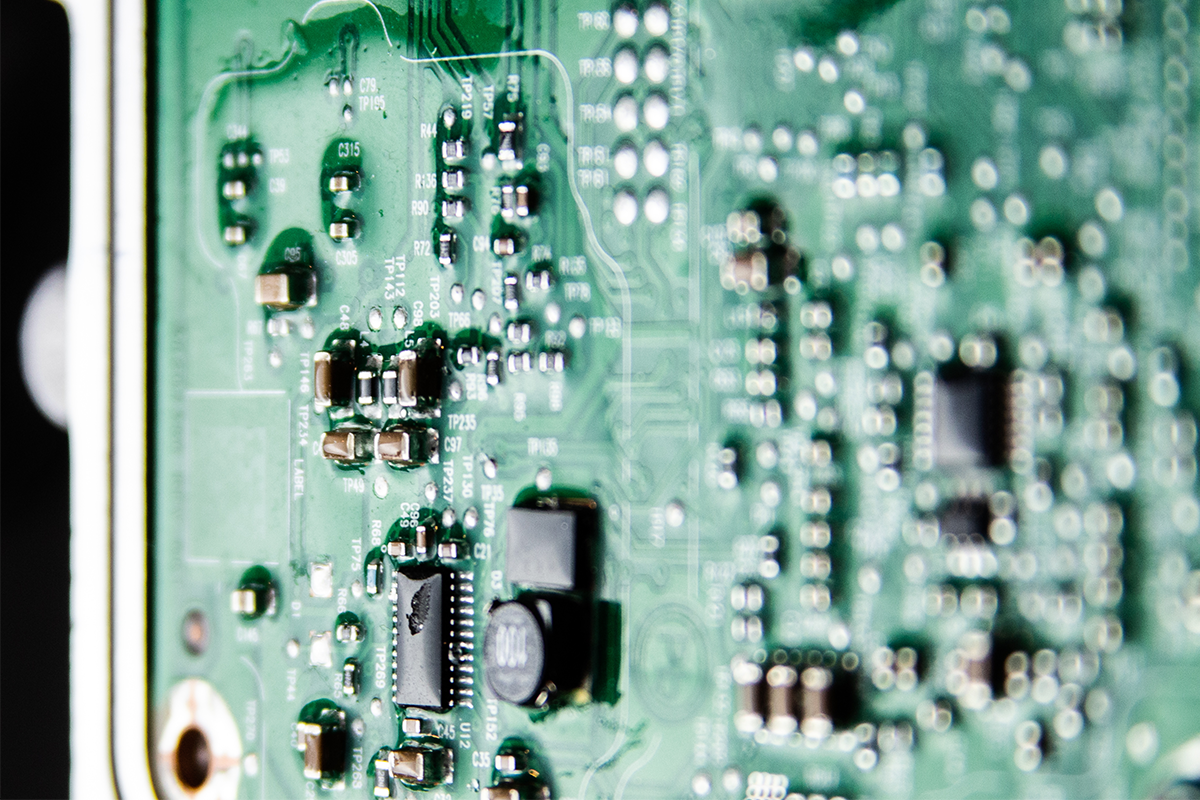

Electronics

Ensure Surface Cleanliness in Electronic Manufacturing

Rapid expansion of electronic use in all industries drives production volume and requires manufacturers to pay close attention to material surface quality. To ensure these electronic components survive common environmental threats, innovative non-destructive testing is needed to verify surface cleanliness and guarantee adhesion.

Common Electronic Applications

- Guarantee surface cleanliness prior to adhesion processes

- Validate presence and uniformity of conformal, hydrophobic and oleophobic coatings

- Eliminate delamination of electronic board stacks

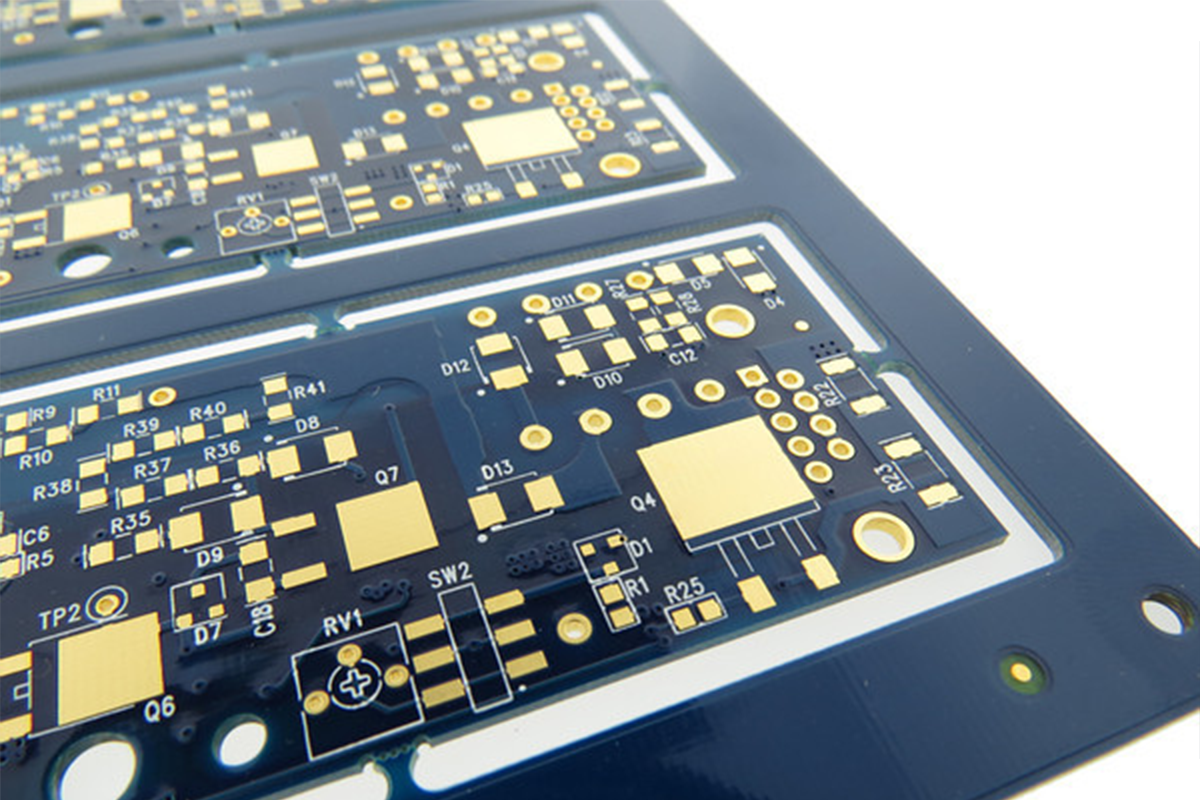

- Validate surface cleanliness on wafers

- Confirm complete removal of flux

- Alternative to ionic contamination testing

- Ensure uniformity of plasma treatment on leap frames

- Audit the quality of thin film deposition on silicon wafers

- Confirm cleanliness of processing equipment such as chemical etching chambers, plasma treatment chambers, CVD and PVD

- Verify ultrasonic cleaning is uniform and effective

- Guarantee print on electronic devices

- Validate surface preparation on glass prior to coating

Our Customers

Unmatched educational resources to expand your knowledge and understanding

Brighton Science is the global leader in surface intelligence.