Fast, Easy, and Accurate Surface Quality Inspection

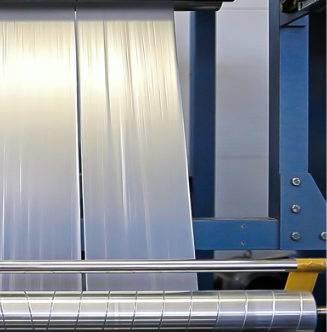

Adhesion is a critical manufacturing process, and ensuring surface readiness is essential to avoiding defects, rework, and costly failures. The Surface Analyst line of products delivers fast, reliable, and non-destructive surface quality inspection—whether in the lab or directly on the production line.

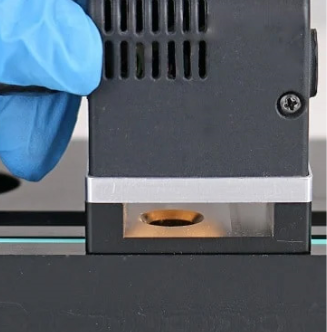

Built on Brighton Science’s patented Ballistic Deposition technology, the Surface Analyst uses quantitative water contact angle measurement to provide instant, repeatable, and objective surface data, giving manufacturers complete control over their adhesion processes.

.png?width=140&height=218&name=Brighton%20Science%20-%20Darwin_XA%20Cell%20(45%20Angle_Left).png)