Networked Solutions

BConnectSM

Optimize Production with Real-Time Surface Intelligence

Solve surface quality issues proactively, prevent costly defects, and control your production process with BConnect.

Invisible environmental factors and everyday human decisions can compromise surface integrity throughout the product development and manufacturing processes, leading to costly defects and failures

Surface energy is a critical factor in creating predictable bonds. Until now, ensuring surface quality has relied on slow, imprecise methods like water break tests and dyne inks, hindering efficiency and increasing the risk of production delays and product failures. These traditional methods are often cumbersome, subjective, and unsuitable for real-world production environments, and critically, don't generate objective data that can be use as part of continuous improvement or quality control.

Water Contact Angle provides an objective, numeric variable that can be used in setting specifications and monitoring Critical Control Points across all areas of your enterprise.

The Data you need, in the Lab and on the Production Line

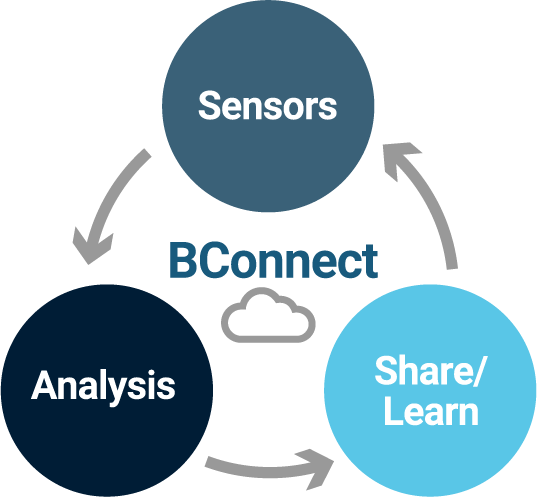

BConnect revolutionizes surface quality management by extending the power of our patented Ballistic Deposition technology. This cutting-edge approach provides rapid, precise, and non-destructive surface measurements in under three seconds, delivering critical insights directly to your fingertips.

Unlike traditional methods, Brighton Science's technology is designed for portability and ease of use on the production floor. This enables real-time monitoring and process adjustments, ensuring consistent surface quality at Critical Control Points in your manufacturing process.

By providing a common language and measurement across your enterprise, BConnect unlocks the power of a true Surface Intelligence network, facilitating seamless collaboration and efficient decision-making across your organization. By keeping all critical stakeholders informed with real-time notifications, BConnect ensures compliance with your processes and specifications and empowers your team to detect and resolve issues before they happen.

Video: Introducing BConnect

Experience BConnect: Two Powerful Solutions

Drive Innovation and Collaboration

Lab Network

Imagine a collaborative workspace where you can streamline surface treatment development, connect with colleagues worldwide, and accelerate innovation. Lab Network empowers your team to:

- Conduct guided experiments to quickly identify and resolve surface challenges.

- Use a structured experiment framework to set clear process specifications.

- Share insights and collaborate across locations to prevent future issues.

- Build a centralized knowledge base for continuous improvement.

- Make data-driven decisions to support production and sales teams.

Unlock the potential of collaborative surface science.

Optimize Production Processes

Process Monitor

Gain complete visibility and control over your production processes with Brighton Process Monitor. This powerful solution enables you to:

- Identify and monitor Critical Control Points to ensure surface quality and compliance.

- Track surface energy specifications across production lines, plants, and shifts.

- Oversee manual and automated processes for consistent performance.

- Get automated alerts to detect deviations and respond quickly.

- Use data-driven insights to optimize production, reduce downtime, and enhance quality.

Optimize your manufacturing operations and ensure consistent, reliable surface performance across your entire organization.

Superior Surface Quality Starts with BConnect.

Faster surface insights. Smarter decisions. Better products.

Request a personalized demo today and discover how BConnect can:

- Solve surface quality challenges faster.

- Prevent costly defects and reduce unnecessary expense.

- Control your production processes.

- Improve collaboration and efficiency across your organization.

BConnect at a Glance

BConnect is a subscription-based service that delivers a complete surface quality management solution. It seamlessly integrates hardware and software, empowering you to:

- Establish surface readiness specifications using BConnect’s experiment framework, ensuring consistency in your production process.

- Leverage Brighton Science’s research and AI tools for deeper analysis and actionable intelligence beyond simple water contact angle readings.

- Share critical surface data across your organization with built-in project management, notifications, and collaboration tools to enhance decision-making.

- Quickly implement and customize your network, which can launch in less than four weeks with full support from our Customer Success team.

- Stay ahead with continuous software updates and hardware enhancements, ensuring zero downtime for calibrations and maximizing your investment.

BConnect Features

-

The Network

-

The Software

-

The Hardware

-

Customer Success

Create Your Own Surface Intelligence Network

Imagine a system where all your surface quality data is connected, accessible, and actionable.

- Easy to set up and scale: No matter your team’s size, building your Surface Intelligence network is simple. Our Customer Success team helps you configure a Network that aligns with your goals, enabling a quick start with the flexibility to grow. With a scalable pricing model, you can start small and expand as you see ROI.

- Tailored to you: We configure your network to your specific needs, and activate features that can be used by Quality teams, SME's, and Plant Managers, granting each user the right level of access and control.

- Focus on results: Our Customer Success Team works directly with you to ensure your network delivers valuable insights and drives real improvements in your manufacturing processes.

- You're in control: Your data belongs to you. You decide who has access and how your network evolves. You can also access the data to pull into your systems with our secure API.

Cloud-Based SaaS Platform

BConnect creates a centralized knowledge base, giving your entire organization access to critical surface quality data in real time. Compare surface cleanliness and contact angle across different treatments, such as plasma vs. manual wiping, and analyze trends using advanced statistical tools like mean, standard deviation, and skewness. Visualize results directly within the system using customizable charts—bar graphs, box-and-whisker plots, and more. Secure API access ensures seamless integration with other enterprise systems, allowing surface intelligence data to flow effortlessly where it’s needed most.

- Seamless connectivity: Each sensor and user is linked to the BConnect cloud, enabling real-time data access and analysis across departments and locations.

- User-based functionality: Receive notifications and alerts tailored to specific roles and responsibilities.

- Secure and customized access: Assign data permissions based on user roles to ensure security and optimize workflows.

- Built-in project management: Organize experiments, track progress, and collaborate efficiently with integrated project management tools.

- Predictable and cost-effective pricing: Brighton Science’s SaaS model ensures a subscription-based structure for budget-friendly, scalable access.

- Continuous improvements: Get automatic updates and enhancements, keeping you equipped with the latest surface quality management tools.

- Enterprise-grade security and compliance: Maintain confidence in data protection, ensuring regulatory adherence and secure operations.

Networked Sensors

For over two decades, Brighton Science’s patented technology has enabled customers to take independent surface measurements in both the lab and on the production line. Now, these devices and data sets can be seamlessly connected, creating a fully integrated surface intelligence network.

Brighton Science continuously enhances its technology by leveraging customer feedback, advanced machine learning algorithms, and telemetry data collected from multiple points within each instrument. This data-driven refinement ensures that hardware and software are always up to date, with no disruption to operations.

- Versatile measurement options: Ballistic Deposition technology is designed for both manual and automated use. The handheld instrument is engineered for ease of use in any production environment, while automated systems integrate seamlessly into robotic and inline applications.

- Always up to date: Instruments receive continuous hardware updates, including improvements to pumps, valves, and features, ensuring optimal performance.

- Zero downtime for calibration: New instruments arrive before recalibration is needed—simply log in and swap devices with no production interruptions.

|

|

BC MobileCollect surface data when and where you want to—not just in the lab—with our flexible handheld units. |

BC InlineIntegrate sensors into your production line for easy, automatic monitoring. |

Your Partner in Continuous Improvement

At Brighton Science, we measure our success by your success. Every BConnect Network is tailored to your specific application—whether you're a small company or a global enterprise. Our Customer Success team ensures your network is configured to align with your business priorities, supporting you from initial setup through ongoing optimization. We partner with you to maximize your return on investment, providing continuous guidance, training, and insights.

- Dedicated onboarding and training: Our team works closely with you to configure your BConnect Network, ensuring a seamless rollout. Training is available through Brighton Academy, scheduled sessions, and AI-driven learning tools.

- Ongoing partnership and optimization: Your Customer Success Manager serves as your strategic partner, helping you track performance, set goals, and continuously improve your network.

- Regular performance reviews: We provide scheduled check-ins and detailed reports to assess how BConnect is delivering value and identify opportunities for enhancement.

- Customer-driven innovation: Your feedback directly informs our software and hardware development, ensuring continuous improvements that align with your evolving needs.

- Benchmarking and best practices: We help you compare your performance against industry standards and similar applications, offering insights to refine processes and maximize efficiency.

Brighton Science is

the global leader

in surface intelligence.

Tell us your goals or challenges, and we can advise you on specific solutions you can put to work immediately or build into your optimization processes.

What could this mean for you?