Confidently Control Surface Quality from Lab to Line

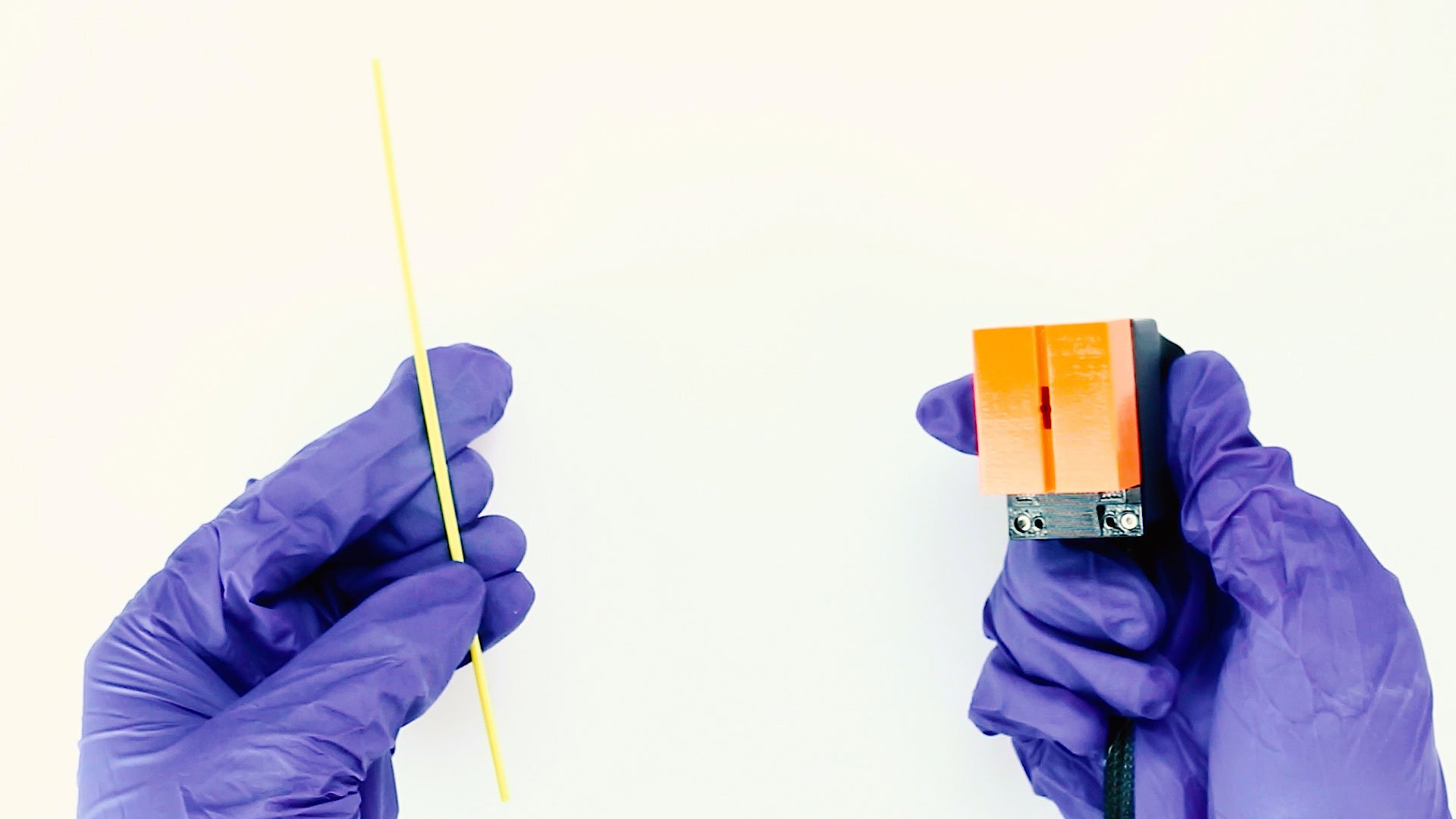

Manufacturers face complex challenges when it comes to adhesion, coating, and sealing—but surface quality doesn’t have to be one of them. The Surface Analyst is a portable, easy-to-use tool that acts like a microscope for your surfaces, revealing the unseen variables that impact your process outcomes through quantitative water contact angle measurement.

Whether you’re developing new specifications, troubleshooting adhesion failures, or maintaining equipment performance, the Surface Analyst empowers your team to capture real-time, objective surface data—anywhere in your facility.

Powered by Brighton Science’s patented Ballistic Deposition technology, it delivers quantitative, non-destructive measurements in under two seconds, eliminating the guesswork of outdated methods like dyne ink and water break tests.

Solve Problems. Optimize Processes. Deliver Results.

- Develop and validate surface specifications to ensure consistency from lab to production line.

- Prevent adhesion failures by verifying surface readiness before bonding, coating, or sealing.

- Reduce waste and rework by confirming surfaces meet spec before production begins.

- Accelerate time to market by optimizing surface preparation during early process development.

- Gain real-time insights that support continuous improvement and process control.

The Surface Analyst puts reliable surface quality data at your fingertips, helping you work smarter, move faster, and build with confidence.