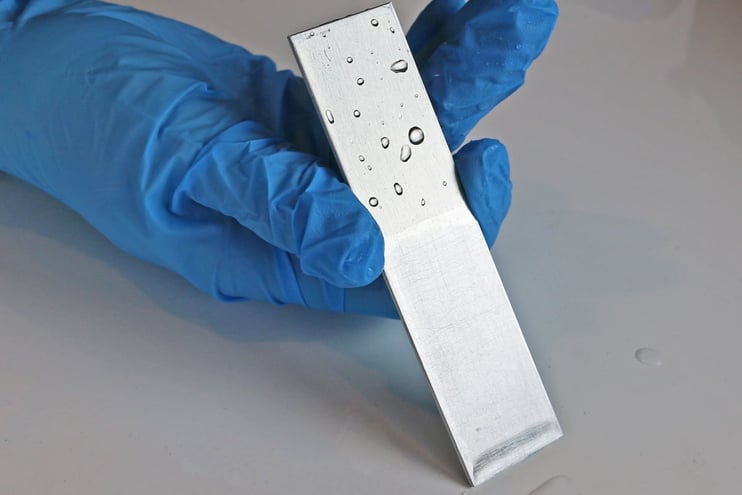

The water break test is a common pass/fail method used to evaluate surfaces for the presence of hydrophobic contaminants, which can be detrimental to the adhesion performance of paint or an adhesive. It is a qualitative means of evaluating surface energy, which is directly related to surface cleanliness.

In this test, a stream of water is visually evaluated as it flows over a surface:

- If it spreads out into a continuous, unbroken sheet, it indicates that the surface is substantially free of hydrophobic contaminants.

- If the surface is contaminated with low surface energy substances, the flowing water will not sheet uniformly over the surface, but rather it will break into rivulets and tend to bead up (termed “water break”).

The test is messy: a relatively large amount of water is used, which has to be removed, and the component must be dried before coating or bonding. Cases of water break tests contaminating sensitive surfaces because of impure water or transfer of contaminants during the drying process are not uncommon. Because the result is only a binary ‘water break free/not water break free,’ it is unknown whether it is too sensitive for some applications or not sensitive enough.

The test is messy: a relatively large amount of water is used, which has to be removed, and the component must be dried before coating or bonding. Cases of water break tests contaminating sensitive surfaces because of impure water or transfer of contaminants during the drying process are not uncommon. Because the result is only a binary ‘water break free/not water break free,’ it is unknown whether it is too sensitive for some applications or not sensitive enough.

Download the full technical paper: Correlating Water Contact Angle with Water Break Measurements as an Indicator of Surface Energy

To read additional information, this paper serves to show how water contact angle measurements are an excellent alternative to water break tests as a process control method.

Struggling with adhesion failures? Been there. Solved that.