Welcome to the Brighton Science Materials Library series.

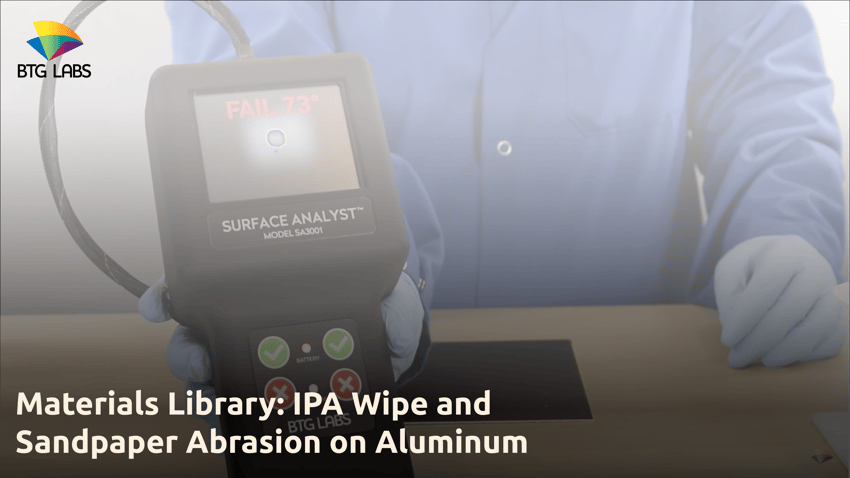

In this series, we use the Surface Analyst to demonstrate how the surface quality of a material changes based on common surface preparation processes. We also give typical contact angle measurements before and after processing to give a general reference for each process as it pertains to the material.

This video demonstrates how the Surface Analyst gives you the ability to measure changes in aluminum preparation. These measurements are used to develop, verify, and monitor surface preparation processes in manufacturing.

Whether you're using the Surface Analyst in the lab or in the hands of an operator on the factory floor, the Surface Analyst gives you real-time business insights while dramatically improving quality control.

Read our eBook about what steps to take to actually get to the root cause of adhesion and cleanliness issues. The “Checklist: Adhesion Failure Root-Cause Analysis for Manufacturers” eBook examines what it takes to truly eradicate adhesion failure from the ground-up.