Cleanliness in manufacturing gains avid devotees all the time. Once the importance of cleanliness is grasped, it’s nearly impossible to think about manufacturing processes without considering the pervasive impact cleanliness has on every aspect and feature of the process.

Cleaning as a means to create superior products has increased in importance over the last several decades as manufacturing across all industries has evolved. Precision machining of parts with lower tolerances for any aberrant particulate (even microns thick debris) has demanded higher precision cleaning. Lightweighting innovations and challenges in the aerospace and automotive sectors have introduced advanced materials that are joined by adhesive bonding rather than mechanical fasteners, by and large. This means the surfaces of these materials need to be cleaned in such a way that they are adequately compatible with the glues and adhesives being applied to them.

Cleaning has been a topic of great interest in electronics manufacturing for some time (the history of which is outlined in greater detail here). Various residues that are intentionally applied to circuit boards or that find their way onto the boards throughout the manufacturing process are known to be the cause of circuit failures. The best method of removing them is to clean them. Additionally, conformal coatings are increasingly needed to protect boards from harsh environments. In order to have confidence in the application of these coatings to the board and component surfaces - those surfaces have to be cleaned to very particular specifications.

Optimize the power of next-gen connectivity with data & surface intelligence.

Medical device manufacturing is much the same. Not only do they utilize electronic components within them, but many are also coated themselves. Medical devices also need to meet standards for cleanliness and sterilization that other industries don’t necessarily. For this reason, the medical device world has always been rather obsessed with cleaning. Cleanliness and sterilization are not exactly the same things, although they can have similar processes to achieve their goals.

Cleaning for manufacturing means creating surfaces ready for bonding, coating, sealing, joining, printing, or painting through processes that alter the material surfaces in various ways. Sometimes that means the removal of substances. Other times it means making an already “clean” surface chemically reactive.

In order to control these changes to the surface, manufacturers need to be aware of the entire production process as a cleaning and adhesion process. Then, and only then, can you appreciate what actually is happening during an intentional part washing or surface treatment step and adequately manage it.

Cleaning for Adhesion

To clean parts and components properly and to get the most out of the equipment and processes used in these operations (which we’ll go into more detail about later), it’s crucial to know the purpose of cleaning. The definition of clean within a particular cleaning process is inextricably tied to the reason the cleaning is occurring in the first place.

Setting up a new cleaning and adhesion process? Download our eBook to make sure your considering all the variables that need to be controlled for consistent, failure-free adhesion: Predictable Adhesion in Manufacturing Through Process Verification.

Defining “clean” will depend on the application and the material you are using, but there are some universal fundamentals about cleanliness that every manufacturer needs to know.

Clean does not always mean clean.

The most basic definition of cleanliness is the removal of particulate from material surfaces. Traditionally, surface quality has been equated to the mere removal of detritus and oils from the surface.

When the goal is predictable, reliable adhesion, however, particulate removal is an incomplete definition of clean.

When we talk about cleanliness for adhesion, we are talking about creating a surface with a precise and knowable chemical composition - or chemical cleanliness. Materials Science chemists define a surface as the top 1- 3 molecular layers because these are the molecules that are actually coming in contact with the adhesive or coating. It may sound bizarre, but if the elements present within these few layers are able to create a strong chemical bond, then the glue, physical vapor deposition coating, chemical vapor deposition coating, Parylene coating, ink, paint, epoxy, weld, or any other type of bond will meet any strength requirements.

Cleaning with the purpose of removing particulate can have the unintended effect of changing the chemical composition of the surface, but if this is a secondary and unexamined result, then it’s impossible to know if the cleaning has been sufficient.

Cleaning with the purpose of creating a surface with pre-specified chemical characteristics focuses the entire process on a definition of clean that is more precise and useful than mere particulate removal. Moreover, this definition of clean is measurable, traceable, achievable, and predictable with the right cleaning equipment and process controls in place.

Know What You’re Cleaning

The types of contaminants (particulate or chemical) that need to be cleaned from a surface or altered, and the method to make these changes, depends on a couple of things. The material a part is constructed of, how it is designed, and the manufacturing environment all affect what cleaning techniques are required.

Metals, polymers, and composite materials all have very distinct characteristics that require different types of cleaning to create and preserve the most ideal surface for adhesion. And within those broad categories, various types of each can have chemical baselines and part-forming processes that vary tremendously. The kinds of equipment and processes the materials come into contact with throughout the manufacturing cycle have a big effect on what kind of contaminants might be deposited onto the surface. Also, the complexity of the design of a part might mean a more or less precise technique is needed to get into blind or drilled holes, internal passageways, sharp inside corners, rough surfaces, or around unusual geometries.

Contaminants that could potentially migrate to a material surface in a manufacturing environment can include machine oil, human skin, and oil, casting sand, metal shavings, polishing compound, salts, mold release, stearate, and even unrinsed solvent from an upstream cleaning step. The list goes on and on.

Cleaning Strategies for Great Adhesion

To fully understand what the best cleaning approach for your adhesion process is, it's important to rely on expert consultation. A manufacturing process and materials expert can guide you through a selection of the best equipment and approaches, and they can offer keys to optimizing these processes.

Here’s a digest of sorts of various cleaning methods that manufacturers employ to clean and prepare surfaces for adhesion. Each entry also goes into things manufacturers need to be aware of when using these approaches in order to get the most out of them, based on the expertise of Materials Scientists who closely study the effects of cleaning for failure-free adhesion.

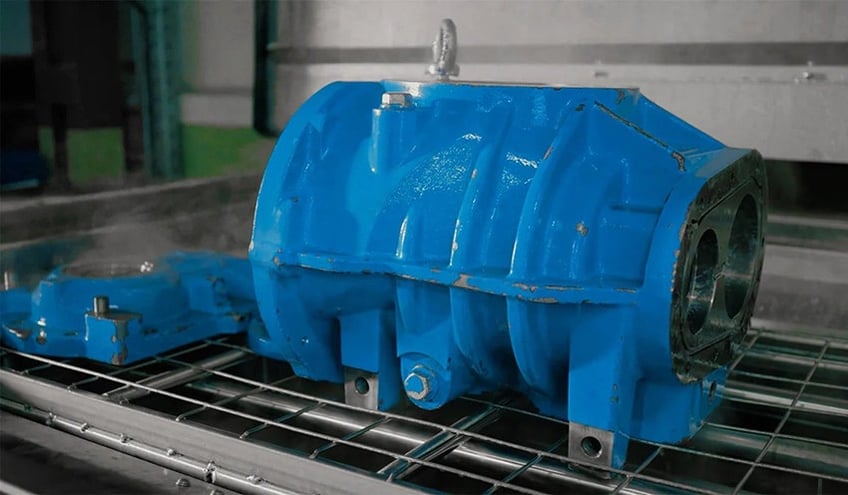

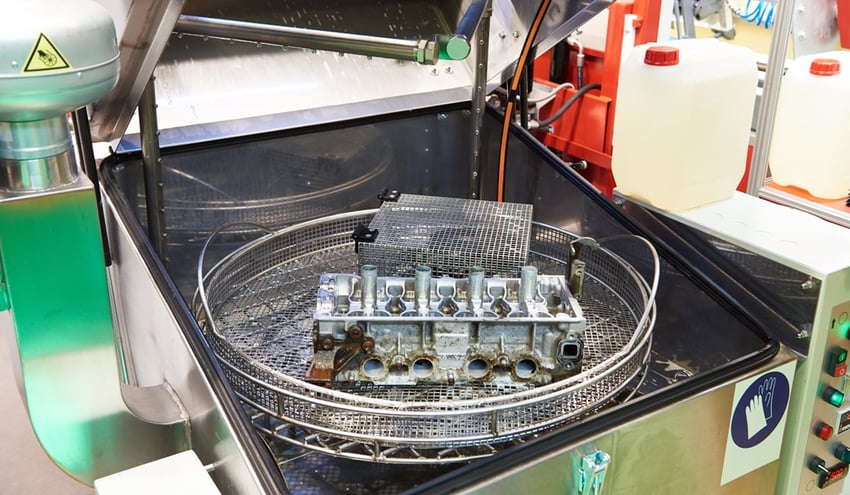

Parts Washing and Ultrasonic Cleaning

For years, parts washing has been widely used and effective in ensuring a part is clear of particulate, especially when gaskets were more commonly used for sealing applications. Several industries have transformed their sealing operations with form-in-place gaskets (FIPG), and these parts, and any parts to be painted or coated, require chemically clean surfaces within known parameters to seal successfully. So parts washers like spray washers, immersion washers, and solvent washers may not be enough.

Ultrasonic cleaning utilizes minute pulses in a solution or water to clean high-reliability parts more precisely. Parts washing and ultrasonic cleaning can be effective in ensuring parts are chemically clean, but the effectiveness of the cleaning process is influenced by many factors:

- Because parts can enter the washing process in various states of cleanliness, the effectiveness of the washing process may not be sufficient for excessively soiled or contaminated parts.

- The quality of the cleaning solutions degrades as parts are cleaned. If the cleaning solutions are not monitored and changed as appropriate, the cleaning process loses its effectiveness.

- The washing process may not be effective on certain contaminants like the ones listed above.

- Washing systems that include sprayers have a greater tendency to not clean uniformly depending on where the sprayer is actually directed at on the part being washed. Sometimes this is adequate, but for applications requiring high-precision cleaning, a spray wash may be too variable in its consistency.

- Parts entering the cleaning process are not always at the same baseline of cleaning, and this is seldom recognized or compensated for.

- Contaminants can be introduced after the washing process, and the surface quality of parts degrades over time as they are stored in inventory.

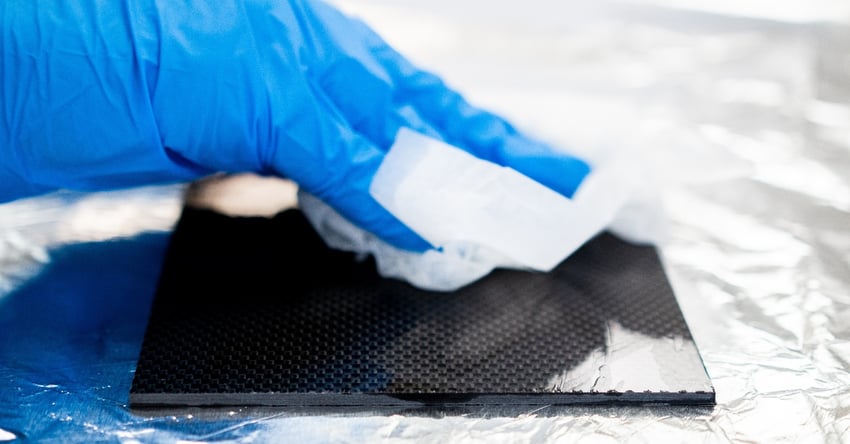

Manual Abrasion and Solvent Cleaning

This is a very common method in most manufacturing processes to modify and clean surfaces of oils and particulate. This manual process primarily involves an individual soaking a cloth with solvent or using a sheet of sandpaper and pulling it across a surface to clean it. Manual cleaning relies on the employee to consistently use the proper techniques every time and to constantly monitor the procedure for possible contamination from the tools being used or due to doing the cleaning in an improper manner. Manual wiping and abrading can properly prepare a surface. However, there are several variables that should be considered to ensure success:

- Wiping should be uni-directional, and the wipe should be changed or rotated after each swipe. Many people wipe in a circular motion which does not remove the contaminants; it simply spreads them around.

- Cleaning cloths may contain chemicals that transfer to surfaces and leave behind residues that can adversely impact proper adhesion. Even a new package of clean cloths from a supplier may include impurities that transfer chemicals that negatively impact adhesion.

- It is quite common for cleaning solutions to be contaminated. For example, if a cloth used for wiping off parts is repeatedly dipped into a container of cleaning solution after wiping down parts, the solution itself soon becomes contaminated.

- The order of the sanding and wiping processes needs to be considered. If a part is sanded before it is wiped clean, the contaminants are pressed deeper into the surface, and the wiping process may no longer be effective.

- Certain sandpapers are better suited for cleaning a particular substrate than others. For example, sandpaper coated with zinc stearate to prevent wear to the paper may transfer the stearate to the material and prevent a sealant or glue from bonding appropriately.

- A particular solvent may not be effective against certain contaminations.

Grit and Media Blasting

This method of surface preparation usually involves a part being placed within a chamber and then pummeled with various hard substances (such as aluminum oxide, glass, or plastic beads) to abrade and clean the surface. This can be an effective way of removing stubborn coatings and particulates from a surface, but there are several things to keep in mind when employing this in your adhesion process, including:

- Media blasting can be an imprecise cleaning method. It may not be effective at cleaning in difficult-to-reach spaces on parts and needs to be monitored for consistent, uniform cleaning across the surface.

- When media blasting, it is common practice to reuse the materials to prepare more than one surface. If the media used is not thoroughly monitored, it is highly likely that contaminants picked up from one surface will be transferred to subsequent surfaces.

- Often dust or other debris is created from this procedure that needs to be cleaned off. To be most effective, subsequent cleaning steps need to take into consideration the media used and the types of contaminants that could have been created or left behind.

Controlling Cleaning Processes

A useful rubric for what elements need to be controlled in a cleaning operation is to think about what changes need to be made to the TACT:

Temperature

Agitation

Chemistry

Time

Depending on the equipment and type of cleaning operation, making adjustments to these elements will vary. For instance, some industrial washers, like ultrasonic cleaners, have great agitation (the physical disruption of particulates), so in applications utilizing this equipment, the chemistry of the fluids used needs to be more closely looked at. With abrasion techniques, it's crucial to not spend too much time on a certain area as opposed to others. The amount of time since the part was last cleaned needs to be considered before moving on to the next operation. TACT is just a simplified way to organize the most controllable parameters of most cleaning processes.

Struggling with adhesion failures? Been there. Solved that.

The best way to ensure that these parameters are optimized, that the chemical composition has been adequately created, and to monitor when changes are occurring is to measure the surface cleanliness throughout the process. As we’ve established, contamination can come from numerous places and can be due to many different ineffective procedures. Therefore, measurement of cleanliness and surface quality needs to happen not only before and after every cleaning step but also when components arrive from suppliers, before and after storage or handling, and anywhere else where the surface has the opportunity to change. These places are called Critical Control Points, and they need to be guarded with inspection equipment that is sensitive to the aspects of cleanliness that are most important to adhesion - namely, chemical cleanliness.

To learn more about how to set up a cleaning and adhesion process that predictably produces the highest quality products, download our eBook "Metrics That Matter: Quantifying Cleaning Efficacy for Manufacturing Performance."