When cleaning invisible contaminants from a surface, you may ask yourself, "How do I know when the surface is clean, or how clean, is clean enough?" These are common questions that product development teams ask when developing new products that require surfaces to be thoroughly cleaned in order to receive an adhesive, coating, paint, or print.

It may seem obvious, but to ensure success in these applications, surfaces must be properly cleaned, or manufacturers run the risk of bonding and coating failures. Simple enough, but if that's all there is to it, then why do failures in these applications still occur?

What Does it Actually Mean to Have a Clean Surface?

The industry has the bread of this sandwich figured out. There are proven and widely used methods for controlling adhesive and coating composition as well as controlling the application and curing process. But a key ingredient is lacking—a relevant definition of the word “clean” as it relates to the quality of the surface state.

The current industry standard of “clean” does not consider true surface cleanliness. Instead, “clean” is often determined by monitoring process parameters. For example, the wash Millipore test quantifies the amount of particulates in a wash tank by filtering a sample of wash solution through a filter paper and measuring the dry weight of the filter paper before and after. This test provides some information about the wash tank solution but gives no indication of the chemical cleanliness of the part surfaces exiting the wash.

Rethink your adhesion manufacturing processes with Surface Intelligence.

How Can We Evaluate Chemical Cleanliness?

|

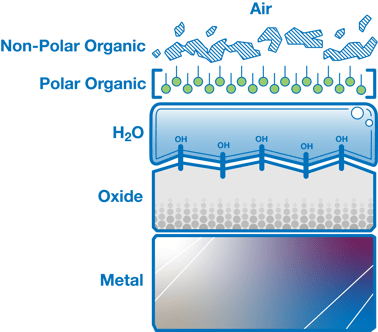

The methods used to determine if a surface has been properly prepped (such as dyne ink, water break tests, and other destructive laboratory methods) have proven themselves to be costly, ineffective, and a dead end when it comes to truly understanding what is causing adhesion failures. Consider the top few molecular layers of a surface—the surface that you can’t see and won't be evaluated by any of the aforementioned methods. If you have a layer of—for lack of a better word—molecular crud (Figure 1.) covering up your baseline material, it’s likely you’ll run into difficulties when bonding or coating. However, if you’ve successfully created a surface that’s clean on a chemical level, you’re bound to have greater adhesion success. |

|

How Clean, is Clean Enough?

Until now, there hasn’t been an objective and reliable way to answer this question. Successfully cleaning a surface directly correlates to the adhesive ability of the surface. In order to get something to stick reliably, the surface must be clean. How we define that parameter is different for a variety of materials.

For example, you clean your car differently than you clean your dishes. Why? Because a car rides on the road through rain, smog, dirt, maybe mud, and the other is a vehicle for your food.

At Brighton Science, our answer to the “clean enough” question is, “Depends on what you’re doing.” There are dozens of critical surface preparation processes that exist for a number of different applications. The surface of PET used for food packaging is prepared differently than a nut plate for a fighter jet.

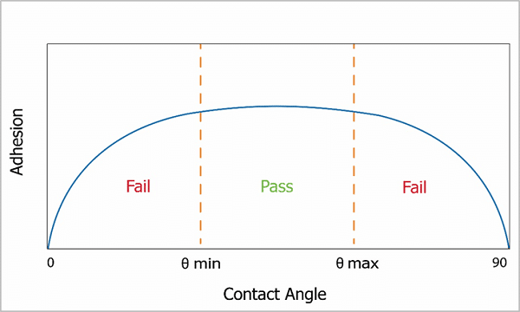

One thing that all surface preparation processes have in common is that they have a range of contact angles that are needed to achieve successful adhesion. Figure 1 exemplifies that for optimum adhesion, there exists not one contact angle but a range of contact angles that can be acceptable in order to properly adhere two surfaces together.

Figure 1. Pass range for successful adhesion.

Figure 1. Pass range for successful adhesion.

Each surface preparation process is specific to its application or its final goal. Surface preparation processes also differ depending on the material.

Contact Angle Specifications Redefine the Industry Standard of "Clean"

Using digital contact angle tools like the Surface Analyst, product teams can develop surface cleanliness specifications for new products and surface preparation processes based on data rather than guesswork. When implemented from the very beginning of a new product's development, contact angle cleanliness specifications create a common language and cleanliness expectation that is used across the organization and even the supply chain—from R&D to product development and all the way through mass production.

Managing critical cleaning processes using data decreases risk throughout the product's development lifecycle, reduces waste, and time spent by product development teams fighting fires caused by a lack of visibility into surface quality, eliminates adhesion and coating failure, and results in a more reliable end product.

Optimize the power of next-gen connectivity with data & surface intelligence.

How to Create Contact Angle Cleanliness Specifications

Thanks to state-of-the-art equipment such as XPS (X-ray Photoelectron Spectroscopy), FTIR (Fourier Transform Infrared Spectroscopy), and the Instron, Brighton Science's Materials and Processing Laboratory has the unique ability to dissect surface preparation processes by determining surface chemistry and composition, finding the failure tolerance for bonds, and determining the appropriate contact angle range to get the surface where it needs to be in order to perform as expected.

Brighton Science is here to help you answer the question, “How clean is clean enough?” by helping you build the appropriate surface quality specification, choose the proper cleaning equipment or technique, and streamline product quality compliance from your supply chain.

So, whether you’re developing the next electric vehicle that's solely adhered together, dreaming of new ways to revolutionize the use of advanced coatings, or using adhesives to make personal electronics perform in ways we've never imagined, Brighton Science is ready to partner with your team to help you know for certain that you are cleaning surfaces the way they need to be cleaned to perform as expected.

Don't settle for inefficient cleaning processes! Download our free industrial cleaning guide, "Metrics That Matter: Quantifying Cleaning Efficacy for Manufacturing Performance," and empower your teams to achieve optimal results.