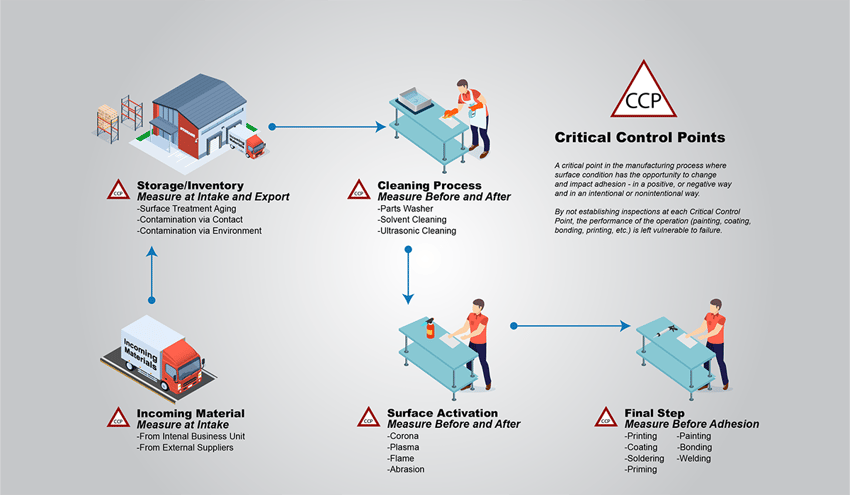

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency.

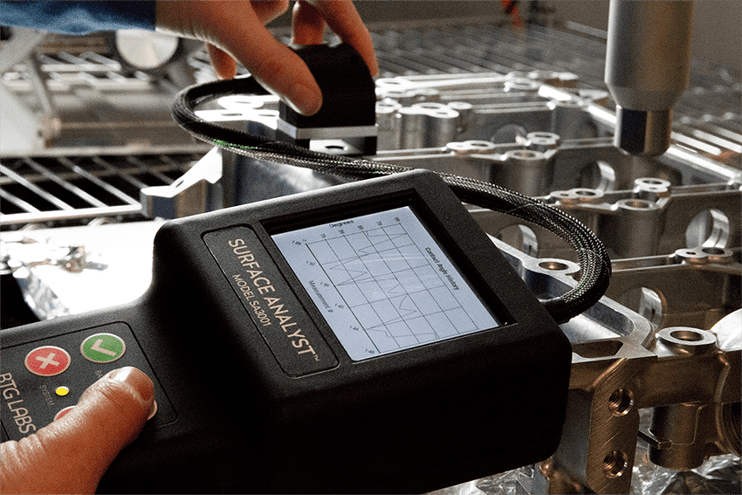

Brighton Science has a versatile suite of solutions for surface analysis based on water contact angle. Industrially robust, fast, and repeatable, these give Product Development, Process Engineering, and Quality Control the tools they need to optimize processes and innovate.

Empowering Efficiency, Innovation, and Quality Across Applications

Where is the need for surface analysis most strongly felt, and who requires the technology? Three business functions stand out:

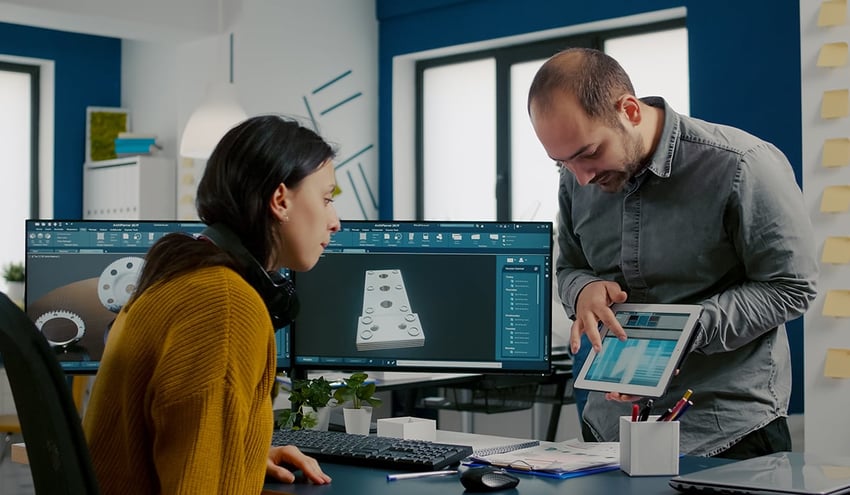

1. Product Development Engineering

Surface analysis technology significantly contributes to two key phases within Product Development Engineering: process development and material qualification. During process development, this technology offers invaluable insights to optimize surface preparation, storage, handling, and packaging procedures, ensuring components remain contamination-free.

Material Selection

The selection of materials is a critical determinant of product quality. This encompasses raw materials, as well as components, adhesives, sealants, coatings, inks, and labeling. Surface analysis technology expedites the evaluation of materials from diverse suppliers, empowering development engineers to make informed decisions regarding optimal material and component choices. For instance, by streamlining the identification of appropriate cleaning methods, development timelines can be accelerated through reduced sample usage and iteration cycles. Additionally, this approach facilitates establishing reliable control substrates essential for assessing coating, sealant, and adhesive performance. Storage conditions, packaging, and processing intervals are further variables that demand careful consideration.

Surface Preparation Specification

Procedures for surface preparation are an important part of process development. Before developing the preparation protocol, consider which processes to use—solvent cleaning, grit blasting, or something else. Without a surface analysis tool, determining optimal values and parameters requires extensive testing and analysis.

2. Process Engineering

Within the Process Engineering function, surface analysis supports problem-solving and process improvement. Brighton Science solutions are highly portable, so an engineer can take them around the factory to make spot measurements as and when needed.

Equally important, this best-in-class equipment provides instant visibility without requiring samples to be sent to 3rd party laboratories or remote analysis. The ability to conduct experiments or assign tasks globally, with on-site analysis of real-world parts in different locations, provides substantial advantages. This approach accelerates data acquisition and enables swift problem resolution and process optimization.

3. Quality Control

For the Quality Control function, surface analysis enables track, trend, trace, and alert capabilities. This refers to quickly identifying when a change in the readiness of a surface for bonding has occurred, identifying the materials and products affected, and alerting those who need to know. Personnel can be trained to monitor using an objective value quickly and easily – easing training issues associated with labor turnover. Emails are automatically sent when a surface is drifting out of spec. Documentation is easy and automatic – easing Quality standard compliance and documenting issue resolution.

How Brighton's Flexible Solutions Empower Every Industry

Brighton Science has helped hundreds of manufacturers solve thousands of problems across a wide array of industries. Here are some examples:

- Automotive: Control the sealing of battery packs in EVs and ensure high-performance adhesive bonding of glass windshields and sunroofs to vehicle structures.

- Aerospace & Defense: Validating preparation of metal and composite surfaces before bonding and coating.

- Building Materials: Many materials undergo laminating, printing, and bonding processes. Vinyl flooring and window construction are both examples. Surface analysis confirms that surface preparation was correctly performed, preventing adhesion failure that results in waste and customer complaints.

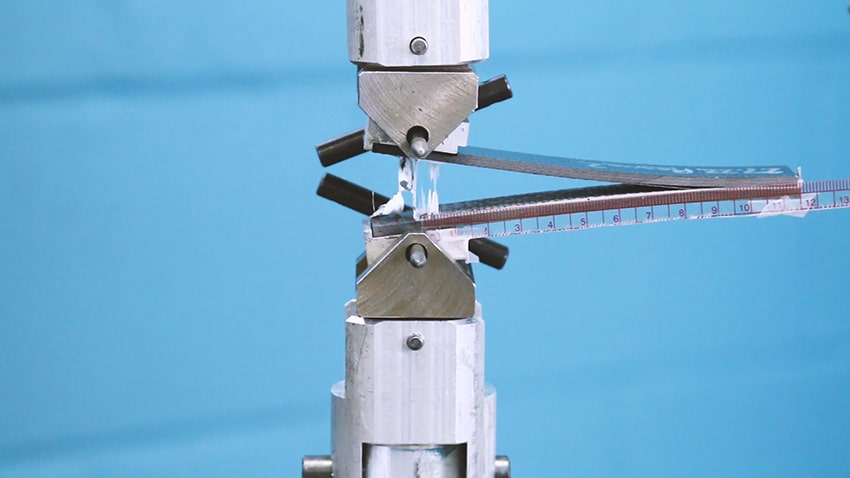

- Adhesives: Bonds only form if surfaces are in the right condition for the application. In the adhesives industry, surface analysis enables data-driven insights to eliminate customer complaints related to surface preparation or bond quality. It provides a vital sales tool for faster application development and better customer technical support.

- Consumer Goods: Surface analysis technology supports the development of flame and corona surface treatments before printing.

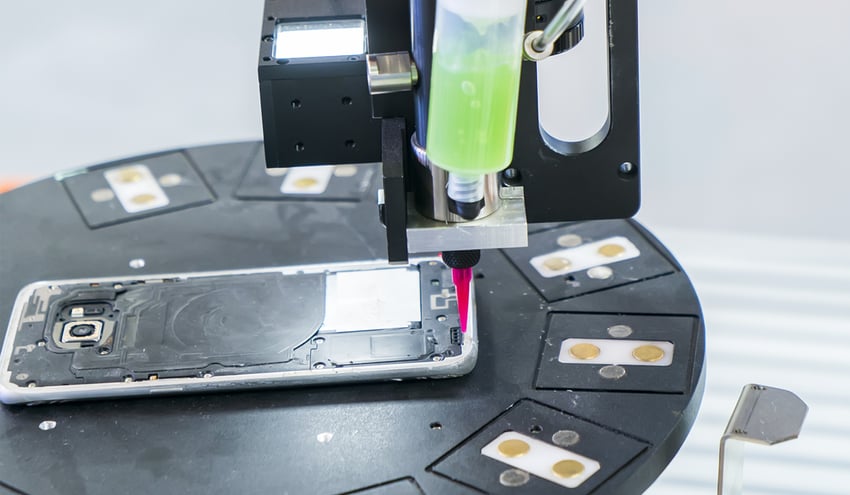

- Electrical/electronic manufacturing: Surface challenges arise in many areas, including TFT display bonding, validation of oleophobic coating, and applying conformal coatings on PCBs. Silicone contamination detection is another common issue.

- Metal forming: Surface cleanliness is essential for consistent results in welding and brazing operations. Brighton Science surface analysis tools can validate material cleanliness and improve yields.

- Supply Chain Compliance: Surface analysis tools allow you to quickly and easily check whether suppliers send uncontaminated, well-prepared surfaces.

Seeing the Unseen: How Surface Analysis Optimizes Your Surface Activation Strategy

Surface activation is the precursor to many adhesive or coating applications. Surface activation equipment manipulates the surface energy of a substrate to ensure strong bonds form between the substrate and the application.

Surface energy can't be observed directly, so measuring it is the only way to know if a substrate is ready for coating or adhesive bonding. Several methods exist, some requiring expensive laboratory equipment and highly trained operators. Two further limitations of laboratory testing are the time delay, which can hold up production, and the fact that it can only sample a small coupon cut from the material being used.

Most industrial surface energy measurement techniques lack resolution and repeatability. Brighton Science's water contact angle measurement technology overcomes these limitations. There are four widely used surface activation methods, and water contact angle measurement can support all of them. Here's an overview:

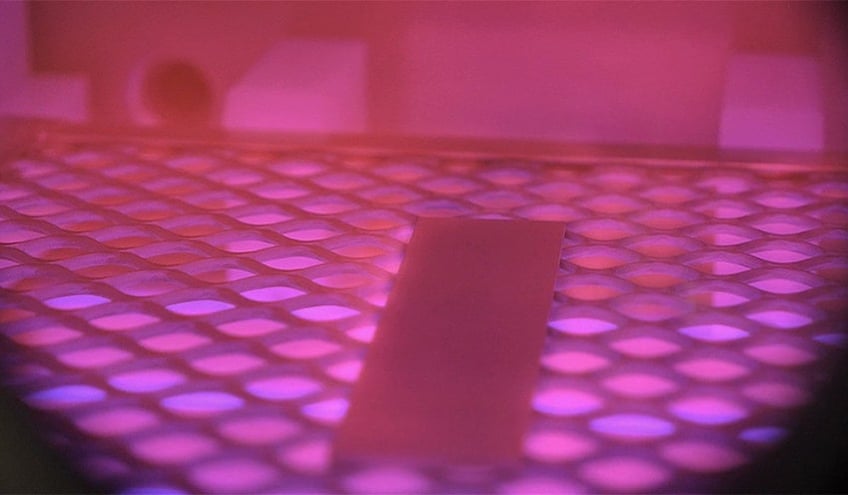

- Atmospheric plasma: Water contact angle supports process development work, principally optimizing speed x distance parameters, and enables incoming quality checks (IQC) on material before plasma treatment.

- Corona treatment: Water contact angle measurement supports optimization of line speed x wattage process parameters and can signal when electrode maintenance is needed.

- Flame treatment: Water contact angle is used for both process development and in-process inspection.

- Vacuum plasma: This activation technology uses a water contact angle for process validation and is a predictor and qualifier of vacuum chamber maintenance work.

Understanding Surface Chemistry: Brighton Science Solutions for Effective Cleaning

Cleaning underpins surface activation: if the surface isn't contaminant-free, activation will, at best, be inconsistent. Surface cleaning mechanisms are either chemical, like an acid etch, or mechanical, like a grit blast. In all cases, surface analysis is a tool for improving the mechanism's effectiveness. For example:

- Chemical Cleaning: Two widely used processes (acid etch and phosphoric acid anodization (PAA)) allow surface analysis to signal when cleaning chemistry has become ineffective and needs to be changed. A related use is defining how clean a surface needs to be.

- Grit blasting: There are many different types of grit, but all break down with use. Surface analysis helps select the correct grit for an application and identify when it needs changing. It's also used to define a "good" grit blast objectively.

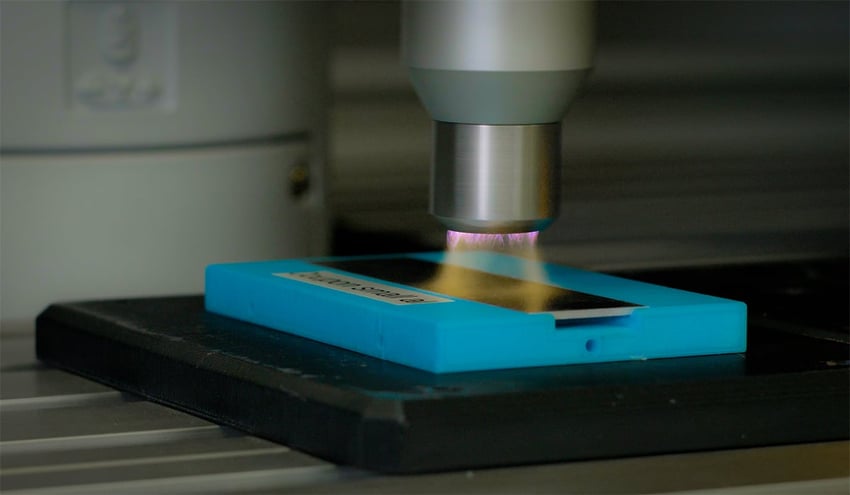

- Laser Ablation: Surface analysis defines optimal unit energy and distance parameters for process validation. It also adds objectivity to scheduling the preventative maintenance task of cleaning protective windows.

- Sanding/abrasion: Its uses include verifying that the right sandpaper has been selected and helping to avoid over-sanding composites. In production, tests after sanding confirm that the job has been done to the required standard.

- Solvent wipe: Surface analysis verifies thorough cleaning directly in production. It will also determine when the wrong wipe or solvent is used or if the technique is incorrect.

- Vapor degreaser: Surface analysis reveals when cleaning has become ineffective and when process maintenance is needed. It is also used to set standards for cleanliness.

Surface Science for All: A Universal Tool for Material Characterization

Brighton Science's technology works on all the following materials and surfaces:

- Glass

- Metals

- Ceramics

- Certain textiles

- Composites

- Polymers

This method is only applicable to solid materials. Liquids, powders, and absorbent substances are incompatible because they cannot form the requisite "beading" necessary to measure contact angle measurements.

Water Contact Angle FAQs

Q: Can water contact angle be measured on vertical surfaces?

Yes, water contact angle measurements can be accurately measured on vertical surfaces.

Q: Can water contact angle be measured on a surface upside down?

Yes, feasible. Watch the Brighton Science video "Measuring Different Orientations" to see it in action.

Q: Can you utilize surface analyst technology on concave or convex parts?

Yes, surface analysis technology can evaluate both concave and convex surfaces.

Q: What is the smallest measurable area for a water contact angle?

Current technology allows contact angle measurements on areas as small as 1 square millimeter.

Q: Will surface roughness impact contact angle measurements?

No, surface roughness does not impact measurement accuracy. Read this article to learn more.

Achieving Quality Through Surface Analysis

If you bond, coat, paint, seal, clean, or manufacture these materials, you need objective surface measurement at one or more points in your product development and production processes. This article has reviewed the industries and applications that currently use and could use the BConnect surface analysis technology to address their product development and manufacturing needs.

To learn more about leveraging surface analysis technology to optimize the product lifecycle, download this eBook, "The Future of Manufacturing: A Guide to Intelligent Adhesive Bonding Technologies & Methodologies."

.jpg?width=850&height=495&name=metal-brazing-copper-component%20(reduced).jpg)